IN THIS ARTICLE

Introduction: Your garage floor isn’t just a surface on which to park your car. It supports the weight of your vehicles and is the stage for various activities, from car maintenance to DIY projects. However, many homeowners overlook the importance of maintaining their garage floors. Over time, concrete garage floor settlement and wear and tear can take a toll, leading to cracks, pits, and uneven surfaces.

But fear not! Garage floor raising and coating can revitalize your garage, providing durability, aesthetics, and protection. In this comprehensive guide, we’ll delve into the why, the how, and the benefits of this transformative process.

Why Raise and Coat Your Garage Floor? Before diving into the nitty-gritty of garage floor raising and coating, let’s understand why it’s essential. Your garage floor faces a barrage of challenges daily – vehicle traffic, chemical spills, moisture, and more. Over time, these factors can lead to cracks, erosion, and deterioration, compromising the structural integrity of your garage.

Raising and coating your garage floor addresses these issues in several ways:

- Repair and Prevention: Raising your garage floor can correct uneven surfaces and support your garage floor, preventing further damage.

- Enhanced Durability: Coating your garage floor adds an extra layer of protection, making it more resistant to stains, abrasion, and chemicals.

- Improved Aesthetics: A fresh coat of epoxy or polyurethane not only protects your floor but also enhances its appearance, giving your garage a polished and professional look.

- Increased Property Value: A well-maintained garage with a raised and coated floor adds value to your property, making it more attractive to potential buyers.

Now that we understand the importance let’s explore the steps involved in raising and applying a garage floor epoxy coating your garage floor.

Step 1: Preparation is Key. Like any successful project, preparation is crucial for garage floor raising and coating. Here’s what you need to do:

- Clear the Space: Remove all items from your garage, including vehicles, tools, and storage items. This will provide ample space to work and prevent damage to your belongings.

- Raise or level the Garage Floor: If your garage floor is sinking, have the floor raised through mudjacking or slabjacking.

- Clean Thoroughly: Sweep away any dirt, dust, and debris from the floor surface. Use a degreaser to remove any oil or grease stains. A pressure washer can be highly effective for this task.

- Repair Cracks and Pits: Fill in any cracks or pits in the floor using a concrete patching compound. Smooth out the surface with a trowel and allow it to dry completely.

Step 2: Raise the Floor Now comes the exciting part is raising your garage floor to create a smooth and level surface. There are various methods for achieving this, depending on the extent of the damage and your budget:

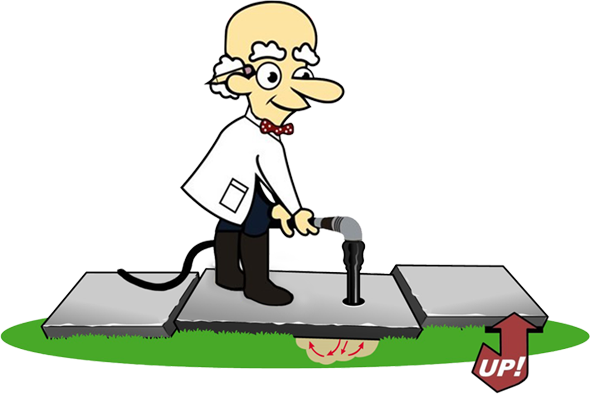

- Concrete Leveling or Mudjacking: This is done by drilling 5/8” to 1” holes through your garage floor, then injecting a cement grout or polyurethane concrete lifting foam under the concrete floor slab to raise it.

- Self-Leveling Compound: Ideal for minor unevenness, self-leveling compound is a quick and easy solution. Simply mix the compound according to the manufacturer’s instructions and pour it onto the floor. It will level itself out and provide a smooth finish.

- Concrete Resurfacer: For more significant imperfections, a concrete resurfacer can work wonders. This product is specially formulated to bond to existing concrete and create a new, durable surface. Apply it with a squeegee or trowel, following the manufacturer’s guidelines.

- Professional Services: For extensive damage or if you prefer to leave it to the experts, hiring a professional contractor is always an option. They have the knowledge, experience, and equipment to assess your garage floor and recommend the best course of action.

Step 3: Coat for Protection and Style With your garage floor now level and smooth, it’s time to apply the finishing touch – a protective coating. Epoxy and polyurethane are two popular options, each with its own set of advantages:

- Epoxy Coating: Known for its durability and chemical resistance, epoxy coating is a favorite among homeowners. It creates a glossy, seamless finish that is easy to clean and maintain. Epoxy is available in a variety of colors and can even be customized with decorative flakes or metallic pigments.

- Polyurethane Coating: If you’re looking for maximum durability and UV resistance, polyurethane coating is the way to go. It forms a tough, flexible layer that can withstand heavy traffic and harsh environmental conditions. While not as glossy as epoxy, polyurethane offers excellent protection against stains and abrasion.

- Painting: Unlike epoxy and polyurethane or polyaspartic garage floor coatings, painting your garage floor does not require the same equipment or skill level. While not as durable as epoxy or polyurethane coatings, the advantages are that it is within the skill level of most homeowners, is less expensive and can be touched up easily should an area failure occur such as from hot tires.

Whichever coating you choose, the application process is similar:

- Prepare the Surface: Ensure the floor is clean and dry before starting. If using epoxy, etch the surface with a concrete grinder or acid solution to promote adhesion.

- Mix the Coating: Follow the manufacturer’s instructions to mix the coating components thoroughly. Use a drill with a mixing paddle for best results.

- Apply the Coating: Use a roller or squeegee to apply the coating evenly to the floor surface. Work in small sections, and be sure to overlap each pass to avoid missed spots.

- Add Optional Elements: If desired, sprinkle decorative flakes or pigments onto the wet coating to add texture and visual interest.

- Allow to Cure: Let the coating cure according to the manufacturer’s recommendations before walking or driving on it. This typically takes 24-48 hours, depending on the product and environmental conditions.

You can see an epoxy coating applied in This Old House video: https://www.youtube.com/watch?v=wBeUWXvK0nU

Raising and coating your garage floor is a transformative process that not only enhances the aesthetics of your garage but also provides long-lasting protection against damage and deterioration. By following these steps and choosing the right materials, you can enjoy a smooth, durable floor that will stand the test of time. So why wait? Elevate your garage today and reap the benefits for years to come!

You can read more concrete leveling and repair-related articles by visiting our learning center.

Concrete Crack Repair: Causes,Types, and Solutions

Mudjacking Cost: 5 Factors That Affect It

Or contact us for a professional evaluation from one of our team experts.

Click here to contact Concrete Chiropractor now for a free quote!

- Garage Floor Raising and Coating: The Ultimate Guide - June 4, 2024

- Mudjacking Cost: 5 Factors That Affect It - April 10, 2024

- What is The Average Cost of Concrete Leveling in Belle Mead, NJ? - April 4, 2024