IN THIS ARTICLE

Is Polyurethane Concrete Lifting Foam a Good Idea? Why the Experts Say NO

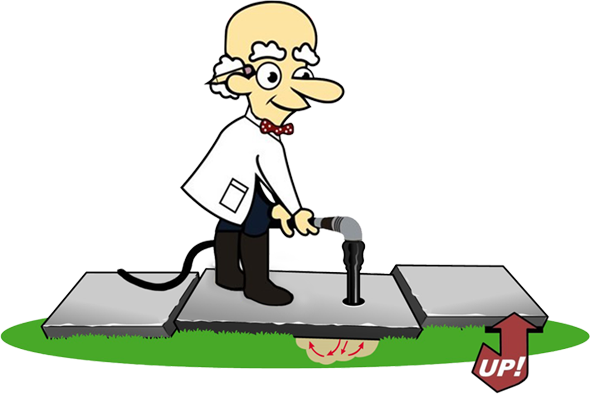

Concrete replacement Is a costly, time-consuming process. When concrete slabs are in otherwise good condition, and your concrete has only settled, a concrete repair method is known as “concrete leveling”. This process typically involves drilling 5/8” to 1” holes through the concrete slab. Then a cement slurry grout with the traditional method known as mudjacking, which has been used since the 1930s, r with a more recent process in which concrete lifting foam is injected. In this article, we explain why Mudjacking is a better alternative.

Can You DIY Mudjacking or Raise Concrete with Foam?

Both processes involve special equipment, which is costly and impractical to purchase for one-time use. This equipment is also not readily available from local rental yards. The materials required for either process also is purchased in bulk and not typically sold in small quantities.

The required skill and experience to raise concrete is also a concern. While it may be possible to raise your concrete, it could be more practical and best left to a reputable local concrete leveling concrete.

How Long Does Mudjacking Last Compared to Poly Foam?

While both processes are used to raise concrete, there are several points to consider when determining long-term job durability.

Settlement

How long has it been since the initial concrete installation, and how much-disturbed fill is the concrete slab resting on? Poor construction practices during initial installation are the number one cause of sinking concrete. If backfill and compaction are not done correctly, the subsoils can sometimes settle for ten to fifteen years.

Examples of this are where there are several feet of fill, such as near a house foundation wall or pool. If the soil reconsolidation process is not finished, concrete sinking will re-occur. This is regardless of the method of repair. Be it concrete replacement, polyfoam, or mudjacking.

Erosion

If water has not been directed away from the concrete area, it can continue to wash out or settle the base soils on which your concrete is resting. This includes downspouts and surface drainage. It is best to contact a local contractor specializing in downspouts and gutters or an irrigation contractor to remedy these issues.

Organic Material

Suppose your concrete has been placed over organic material that decays over time, such as tree roots, old construction debris, or swampy areas. In that case, the ongoing decay will continue to cause concrete slab settlement and failure.

Is concrete leveling with polyurethane foam or poly foam a better system?

It can be difficult for the consumer to sort through the tons of online blogs and opinions. Many are written to specifically steer a customer toward the product or service offered by that company. Although the long-term results of concrete leveling with foam have yet to be determined, job results and studies completed by civil and environmental engineers have concrete experts saying NO for the following reasons.

Material Sourcing

Polyurethane foam is a petroleum-based chemical product derived from crude oil. These products must be processed, trucked, or shipped and distributed. This results in a negative environmental impact and output of CO2 from the shipping of the material. Mudjacking grout is a cementitious, locally sourced product of cement and aggregates such as sand or limestone.

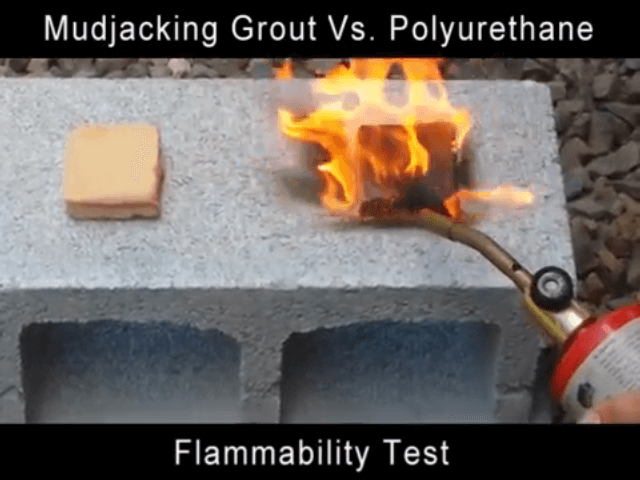

Material Volatility

Poly foam is flammable, and case studies have shown it self-combusts, producing toxic smoke and health-related lawsuits.

Toxicity

Poly foam is made from isocyanates and polyols. Isocyanates are a group of highly reactive chemicals that are an irritant to the eyes and respiratory system. Severe asthma attacks and death have been known to occur from exposure to isocyanates. While a simple mask and skin protection are required when working with cement, working with isocyanates requires a higher level of personal protective equipment as recommended by the National Institute of Safety and Health and the CDC>

Strength

Poly foams have an average strength of 100 psi (pounds per square inch). The material strength is set and cannot be adjusted. Most job specifications require a minimum strength of 500 psi. Which is five times the compressive strength of the poly foam.

However, mud-jacking grout strength can be increased on-site to meet special requirements of 5000 psi. Strengths not achievable with poly foam.

Weight

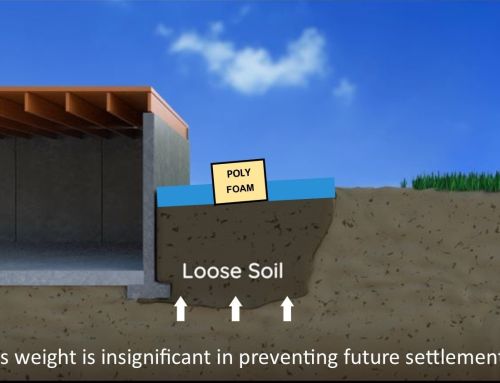

The polyfoam industry states that the foam material will not cause settlement with a weight of 4 pounds per cubic foot compared to 100 pounds per cubic foot for Mudjacking grout. Is this point significant when it comes to concrete settlement? The answer is NO. With an average soil weight-bearing capacity range of 1500 to 3000 pounds per square foot, Mudjacking grout is only 5% of the capacity of the soil.

The number one cause of concrete settlement is loose fill. Soils with no weight whatsoever on the surface will settle and fail. Weight is insignificant.

Recyclability

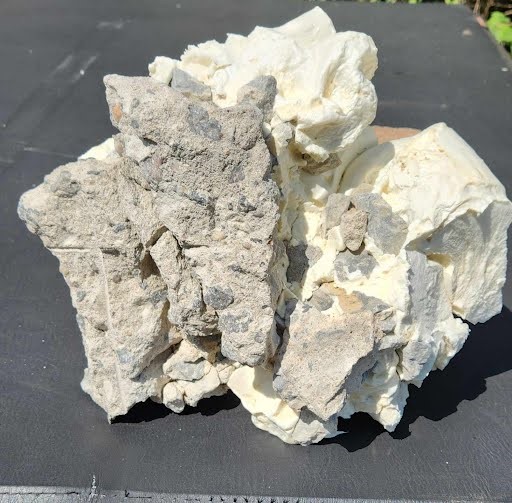

Crushed and reused in disposable concrete, and must be separated. These foams must be brought to a landfill at an additional labor and disposal cost to the homeowner.

Damage to Surfaces

When concrete leveling with poly foam, permanent damage and staining can occur to the concrete surface, home siding, and surrounding areas. While mud-jacking grout can be rinsed and cleaned with water, foam cannot. The foam must be removed with a chemical product which is only sometimes possible depending on the surface.

Higher Product Cost:

Like gasoline, oil, and other petroleum-based products, polyfoam is subject to the oil market.

Future Environmental Concerns

Our society has become more environmentally conscious and is reducing our reliance on petroleum-based products and plastics. We are moving quickly toward the requirement and use of all-natural and biodegradable products whenever possible, with plastic reduction taking the forefront. Disposing or recycling plastic products or “poly foams” will likely become more complex and costly. Concrete has a service life; eventually, most concrete gets replaced at some point due to need or preference.

Why is Mudjacking A Better Process Than Concrete Poly Leveling?

Mud jacking material is natural and locally sourced.

Cement grout is a recyclable material that has been in use for thousands of years.

It is nonflammable and nontoxic. It is much safer for the installation crew, homeowner, and environment.

Does not stick to and damage surrounding surfaces.

Concrete raising with a cement slurry grout does not come with the future unknown costs and regulatory issues associated with plastics or poly.

Slabjacking with cement grout is typically more cost-effective due to the higher costs associated with poly foam.

Who Provides Mud Jacking Near Me?

If you are located in the New Jersey or Eastern PA areas of Buck County, Allentown, or Philadelphia, Concrete Chiropractor’s team of experts has decades of experience raising sunken concrete around all weather conditions. We are a professional concrete leveling service that has helped thousands of homeowners avoid the cost of concrete replacement.

To see what concrete leveling can do for you, click the link below to request an estimate from our seasoned professionals.

Click Here to Receive a FREE Estimate From Your Nearest Location

Want to know more? Check out these related topics or visit our Learning Center

Mudjacking vs. Poly Jacking: Which is The Better Choice?

Concrete Lifting Foam DIY: Raising Concrete Slabs With Canned Spray Foam

Concrete Repair: The Cost of Doing Nothing

- Garage Floor Raising and Coating: The Ultimate Guide - June 4, 2024

- Mudjacking Cost: 5 Factors That Affect It - April 10, 2024

- What is The Average Cost of Concrete Leveling in Belle Mead, NJ? - April 4, 2024