OUR SERVICES

MUDJACKING

Facts & Information to Know

Mudjacking is an eighty plus year old process dating back to the 1930’s. The word is often spelled with variations such as mud jacking or mud-jacking. It is also referred to as: Concrete leveling, concrete raising, or concrete lifting.

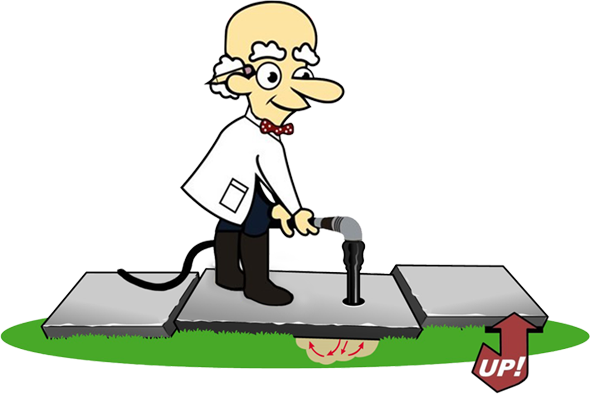

How it's done:

Holes typically one inch, or the size of a quarter are first drilled through the concrete slab. A mixture of Portland cement, sand and other natural, earth-based materials are then mixed and injected beneath the slab with a hydraulic grout pump.

Once the concrete is floated back up to it’s original position, a high strength cement is then used to fill the access holes. Mudjacking has been used successfully for decades to raise pool decks, patios, garage floors, and more as a repair solution. These sinking concrete slabs can not only result in property devaluation and home sales and are often a safety liability that can result in injuries, insurance policy cancellations, and or lawsuits.

Click Here to read our Mudjacking FAQ

The Mudjacking process can take your concrete surface from liable to reliable in just hours, not days! ™

Mudjacking is a time proven process in use for over 80 years. When lab tested to ASTM standards, Mudjacking grout provides strengths five times that of chemical poly foams and can be custom mixed onsite to provide 50 times the strength of foam.