IN THIS ARTICLE

What is Mudjacking (History, Process, Cost)

When concrete slabs settle or become sunken or uneven, it can create various safety hazards, dangers, and structural issues. Here are some potential hazards that can arise from the concrete settlement:

- Tripping and Falling: Uneven concrete surfaces, such as sidewalks, driveways, and patios, can create tripping hazards for pedestrians. Uneven concrete can cause falls, especially for older people, children, or those with mobility issues, due to sudden changes in height.

- Sunken driveways and parking areas can damage vehicles by scraping against the ground or causing jolts on uneven surfaces. This can result in damage to the vehicles’ undercarriage, tires, and suspension systems.

- Water Drainage Issues: Settlement in concrete surfaces can disrupt the natural flow of water, causing puddles, ponding, and poor drainage. Accumulating water can lead to erosion, soil erosion, and potential foundation problems if water infiltrates the underlying soil.

- Sunken concrete can weaken buildings and structures if it affects the foundation or load-bearing parts, causing structural instability. This could lead to cracks in walls, floors, and ceilings, as well as compromised stability over time.

- Aesthetic and Property Value Concerns: Uneven or sunken concrete can detract from the visual appeal of a property. This could potentially reduce its curb appeal and property value, making it less attractive to potential buyers or tenants.

- Accessibility Issues: Sunken concrete can create accessibility challenges for individuals with disabilities. Wheelchair users, for example, may find it difficult or impossible to navigate areas with uneven surfaces.

- Damage to Infrastructure: Sunken or uneven concrete can impact adjacent infrastructure such as utility lines, drainage systems, and landscaping. It might also affect the stability of nearby structures.

- Property owners must be responsible for injuries caused by hazards on their property, like tripping on uneven concrete. Legal actions resulting from injuries can lead to financial burdens and reputational damage.

To mitigate these hazards, it’s important to address concrete settlement issues promptly. You can fix the settlement by mud jacking, replacing the concrete, or using other repair methods. The severity of the settlement and its cause will determine the best approach.

Regular inspections and maintenance of concrete surfaces can help prevent hazards from arising in the first place. If you notice signs of concrete settlement or hazards on your property, it’s advisable to consult with a professional concrete repair contractor to assess the situation and recommend appropriate solutions.

What is Mud Jacking

Mud jacking lifts and stabilizes sunken or uneven concrete slabs in construction and foundation repair. It’s also called slab jacking or concrete lifting.

This method is often used to fix concrete surfaces that have sunk or settled. These surfaces include sidewalks, driveways, patios, and foundations. The sinking or settling is usually caused by soil erosion, poor compaction, or other factors.

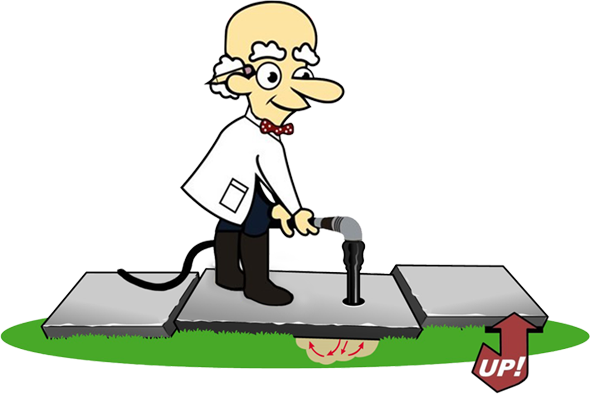

The process involves injecting a mixture of grout (a slurry of water, soil, cement, and other additives) under the sunken concrete slab. This injected grout fills voids in the soil beneath the slab, providing support and lifting the slab back to its original level. The grout hardens over time, providing a stable foundation for the concrete surface.

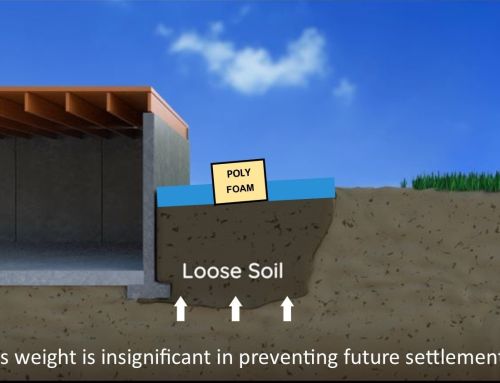

A more recent process that involves the mixing and injection of a two-part chemical product is known as polyurethane foam concrete raising or poly foam. However, these petroleum-based products do come with associated risks and cost due to their flammability, toxicity, and recyclability issues.

The History of Mud Jacking

Mudjacking, also referred to as slab jacking, concrete raising, or concrete flattening, is a process utilized for elevating and aligning sunken or uneven concrete surfaces by injecting a blend of substances beneath the slab. This method has been used for many years to repair and rejuvenate different types of concrete structures. These structures include paths, entrances, patios, and even some small foundation repairs.

Now, let’s take a look at the history of mud jacking. Here’s a summary of the mud jacking history.

Early Development: The concept of mud jacking can be traced back to the early 20th century. In the 1920s and 1930s, engineers and construction professionals began experimenting with different methods to address the issue of sunken or settled concrete slabs. The primary motivation was to find a cost-effective solution to repair and level these surfaces without the need for extensive demolition and replacement.

Invention and Early Use: While there is no specific individual credited with inventing mud jacking, it is believed that the technique emerged as a practical solution through collective experimentation by engineers, contractors, and construction workers. The process involves drilling holes into the sunken concrete, then injecting a slurry mixture—typically consisting of a combination of water, soil, and cement—into these holes. As the slurry fills the voids beneath the slab, it raises the concrete to its desired level.

Advancements and Popularization: Over the years, advancements in materials and techniques have improved the effectiveness and efficiency of mud jacking. In the mid-20th century, as concrete construction became more widespread, so did the use of mud jacking as a repair method. Contractors and professionals refined the process, incorporating better equipment, more precise injection methods, and improved slurry formulations.

Modern Applications: In recent decades, mud jacking has continued to evolve, incorporating new technologies and materials.

Limitations and Alternatives: While mud jacking can be effective for certain types of concrete repair, it’s not suitable for all situations. For instance, severely damaged or deteriorated concrete may require complete replacement. Additionally, mud jacking might not be the best solution for larger-scale foundation issues.

Conclusion: Mudjacking has a history of several decades as a cost-effective method for lifting and leveling sunken concrete surfaces. While the basic principles of the technique remain consistent, advancements in materials and equipment have made the process more efficient and effective. As construction and repair technologies continue to advance, mud jacking will likely continue to adapt and find its place in the range of solutions available for concrete repair and restoration.

The Mud Jacking Process

- Assessment and Preparation:

-

- A professional mudjacking contractor assesses the sunken or uneven concrete surface to determine the extent of the problem and whether mudjacking is a suitable solution.

- The contractor identifies the areas that need to be lifted and levels of settlement.

- Drilling Holes:

-

- Once the assessment is complete, the contractor marks the areas where holes need to be drilled.

- Small holes (usually around 1 inch in diameter, or the size of a quarter) are drilled into the sunken concrete slab. These holes are strategically placed to access the voids or spaces beneath the slab.

- Injection of Slurry:

-

- A slurry mixture is prepared. Traditionally, this slurry consists of a mix of water, sand or limestone, and cement. In modern applications, polymer-based materials might also be used for their lightweight and high-strength properties.

- The slurry is pumped under pressure through the drilled holes into the voids beneath the sunken concrete.

- Lifting and Leveling:

-

- As the slurry is injected, it fills the voids and exerts pressure against the underside of the slab.

- The pressure from the injected slurry gradually lifts the sunken concrete slab to its desired level. Contractors monitor this process carefully to ensure that the slab is lifted uniformly and to the correct elevation.

- Hole Sealing and Cleanup:

-

- After the concrete slab has been lifted and leveled, the drilled holes are sealed using cement materials.

- Any excess slurry that might have oozed out during the injection process is cleaned up.

- Curing and Use:

-

- The repaired concrete surface is typically usable shortly after the mudjacking process is completed. However, slabs subject to vehicle traffic may take a couple of days.

- Allow the repaired area to cure properly before subjecting it to heavy loads or traffic.

Advantages of Mudjacking:

-

- Cost-effective: Mudjacking is often more affordable than completely replacing a sunken concrete slab.

- Mudjacking causes less disruption than demolishing and replacing the whole slab by drilling small holes.

- Quick results: The process can be completed relatively quickly, allowing you to use the repaired area sooner.

- Visual: Mudjacking avoids the unsightly slab color difference associated with replacement.

Limitations and Considerations:

-

- Not good for very damaged concrete: If the concrete is very cracked, worn out, or structurally weak, mudjacking may not work. The concrete may settle again because of the same reasons, which could lead to future settling.

- Older concrete can last as long as new replacement. The sub-soils have had time to fully compact with time. These concrete raising jobscan often last twenty years or more.

- Professional expertise: Mudjacking requires the skills and equipment of experienced contractors to ensure proper execution and lasting results.

Mud Jacking Cost

The cost of mud jacking can vary widely depending on several factors, including the size of the project, the extent of the sunken or uneven concrete, the location, the accessibility of the site, and the materials used. Here are some factors that can influence the cost of a mud jacking project:

- Size of the Area: Larger areas or multiple areas that require mud jacking will typically result in higher costs due to the increased amount of materials and labor involved.

- Depth of Settlement: The depth to which the concrete has settled will impact the amount of slurry material required to lift and level the slab. Deeper settlements might require more materials and labor.

- Accessibility: If the sunken concrete is located in an area that is difficult to access (such as tight spaces or hard-to-reach areas), it may require more effort and specialized equipment, which can increase the overall cost.

- Materials Used: The type of material used for the mud jacking slurry can affect the cost. Traditional mixtures using soil, cement, and water might be more affordable, while modern polymer-based materials could be more expensive.

- Labor Costs: Labor costs vary based on location, experience of the contractor, and the complexity of the project. Skilled labor is essential for proper mud jacking execution.

- Additional Repairs: In some cases, additional repairs might be needed after the mud jacking process, such as patching holes, repairing cracks, or resurfacing the concrete. These can add to the overall cost.

- Geographical Location: Costs can vary significantly based on regional factors, such as local labor rates, material availability, and market demand.

- Preparation Work: If the site requires extensive preparation work, such as clearing debris, removing obstacles, or cleaning the area, these tasks can add to the total cost.

- Warranty and Quality: Contractors who offer longer warranties or higher-quality materials might charge more for their services.

- Market Conditions: Supply and demand factors in the local market can also impact the cost. In areas with high demand for concrete repair services, prices might be higher.

Given these variables, it’s challenging to provide an exact cost estimate without knowing the specifics of your project. However, as a rough guideline, mud jacking costs can range from hundreds of dollars for a small area to several thousand dollars for larger or more complex projects. To get an accurate estimate for your specific project, it’s recommended to contact local mud jacking contractors. They can assess the situation, consider the factors mentioned above, and provide you with a detailed cost estimate based on your needs and location. It’s also a good idea to obtain multiple quotes from different contractors to compare prices and services.

- Garage Floor Raising and Coating: The Ultimate Guide - June 4, 2024

- Mudjacking Cost: 5 Factors That Affect It - April 10, 2024

- What is The Average Cost of Concrete Leveling in Belle Mead, NJ? - April 4, 2024