IN THIS ARTICLE

Mudjacking vs. Poly Jacking: Which is The Better Choice?

Concrete is the number one building material used worldwide, second only to water. See Article.

However, over time, concrete can be damaged from sinking or settlement. Two common methods to repair concrete settlement while avoiding concrete replacement are mudjacking and polyurethane foam injection.

While both methods are used to raise concrete slabs, understanding their differences is essential to choosing which concrete leveling method is right for you. This article provides detailed information on the two methods, including the processes, durability, costs, advantages, and disadvantages of each process when lifting concrete.

By understanding the differences between polyurethane foam injection and Mudjacking, you can select the most suitable method for your requirements to ensure your concrete is restored to its original state, improving its appearance and safety for years to come.

Polyurethane Concrete Raising

Also known as polyurethane concrete lifting foam or concrete leveling with foam, petroleum-derived expanding foam raises concrete slabs. Polyurethane is a manufactured, two-part chemical product that mixes isocyanate with a polyol. As the reaction occurs, the foam product expands, raising the concrete slab.

5/8” or penny-sized holes are drilled through the concrete slab. The polyfoam is mixed and injected through the holes and expands below the concrete, yielding an average compressive strength of 80 to 100 psi. Sufficient expansion to fully support the concrete slab can be difficult as the product sets in 15 minutes, often requiring more drill holes than the mud jacking process.

Polyurethane foam injection can sometimes access tight areas that are not accessible with Mudjacking equipment. However, the concrete lifting foam process can be limited by distance from the truck or trailer that contains the drums of chemical foam and mixing equipment, such as in backyards needing Concrete Pool Deck Repair.

Experienced operators and care when injecting poly foam are critical with Concrete Poly Leveling. Mixing the product for injections generates heat and has been known to self-combust into flames. The product is also toxic and off-gas. Proper personal protective equipment must be worn during installation.

Pros:

- Polyurethane concrete leveling is best in areas with limited access that cannot be accessed with Mudjacking equipment.

- Polyleveling requires a slightly smaller drill hole at 5/8” versus 1” for Mudjacking.

Cons:

- High-density polyurethane foam is flammable and has a history of self-combustion issues and off-gassing during installation, resulting in building fires, health-related lawsuits, and death.

- Concrete recycling facilities do not accept poly foam, which adds additional separation/labor costs and disposal costs during concrete replacement.

- Polyurethane concrete raising foam is derived from crude oil, transported to a refinery, to a distribution facility, and then to the contractor. This often results in higher manufacturing, transportation, and product costs for the homeowner or end user.

- Sticks to and damages surrounding concrete surfaces, siding, railings, etc.

- Foam breaks down over time.

For more information about polyurethane foam products and its benefits and risks, check out https://en.wikipedia.org/wiki/Polyurethane

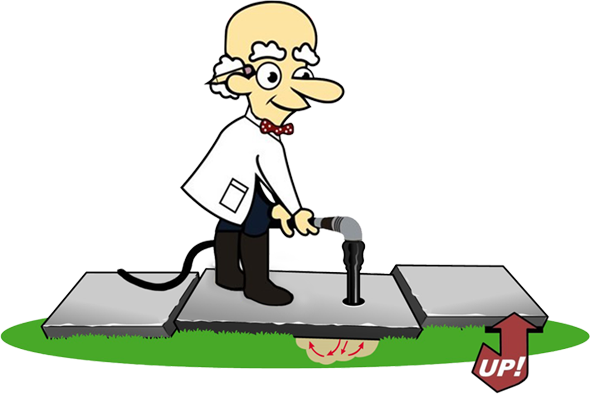

Mudjacking

Mudjacking history dates back to 1930 when a mechanic for the Iowa State Highway Commission named John Poulter used his new invention in Burlington, Iowa. His new invention forced a cement-infused mud slurry through access holes drilled into the concrete. The process is nearly 100 years old, has a history of success on highways and other concrete slabs, and is still widely used.

Mudjacking is also known as cement slurry grout injection or Concrete Leveling. The cement slurry uses various all-natural, earth-based materials from local quarries, such as sand, limestone, and clay. It is mixed with Portland cement to achieve a minimum strength of 500 psi. or higher.

1” or quarter-size small holes are drilled into the concrete slab. The cement grout is injected, fills voids under the concrete slab, and floats it back to its original position. The holes are then patched with high-strength cement.

The cement slurry grout mix can be adjusted onsite. The cement mix can be tightened or loosened, and additional cement can be added to accommodate specific job specifications and requirements.

Pros:

- All-natural, locally sourced materials without the recyclability, flammability, or health risks associated with polyurethane foam.

- Five times or higher compressive strength of poly foam. Strength can achieve 5000 psi. and be adjusted onsite based on application.

- Will not stick to or damage surfaces like polyurethane concrete leveling.

- The product is not petroleum-based, handled, stored, and transported like poly foam, resulting in lower material costs.

- It is easier to control, resulting in a higher job success rate.

- A time-proven method that has proven to be durable and long-lasting.

Cons:

- Requires a slightly larger hole that is 3/8” larger.

- The method can sometimes be limited by poor job access in rare circumstances.

Polyjacking vs. Mudjacking

Researching the advantages and disadvantages of each concrete repair method will help you decide which is best for your application when raising sunken concrete.

While polyurethane foam concrete raising can have certain benefits regarding poor access, it is a newer method with associated risks and additional costs. The product cost when concrete leveling with foam supports deriving the product from petroleum, the chemical companies that must refine and market the product, and storage and transport costs.

In most cases, the risks and costs associated with polyurethane foam make its use unnecessary, without offering any true benefit over the mudjacking process. Mudjacking grout is safe, stronger, and time-proven and has no negative environmental impact like polyfoam.

Limiting the use of poly or plastic is becoming a significant environmental concern. Reducing our dependency and restricting the use of plastic bags, straws, and other plastic products is a growing concern.

Around 85% of plastics wind up in landfills. As environmental concerns and recycling costs increase, polyurethane concrete lifting foam appears to become a less attractive and more costly option for homeowners.

How Long Does Polyurethane Concrete Raising or Mudjacking Last?

Truth be told, concrete settlement is not typically due to material failure but is a result of further failure of base soils. If the base soil that concrete has been placed on has not been fully reconsolidated, further settlement will occur.

Disturbed soils during initial construction have sometimes been known to settle for ten to fifteen years. Regardless of which concrete lifting material is used, the concrete slab will continue to sink, and the lifting material will sink with it until the soil base has reached full settlement.

This is also true regardless of material product weight.

Meanwhile, polyurethane foam boasts a product weight of only 100 psi. Per cubic foot, it is insignificant regarding the cause of concrete settlement.

Average soil bearing capability is 1500 to 3000 pounds per square foot. This is more than sufficient to support a concrete slab with either choice of concrete raising material.

The most crucial step in choosing a concrete-raising contractor is to contact one with enough history and experience to determine the cause of your concrete failure and if your settlement is complete. Concrete Chiropractor® history has shown concrete raising repairs completed with mudjacking in 2000, which are still in place today.

Click here to see a video regarding product weight and settlement.

Why You Should Choose Mudjacking

Mudjacking has several advantages over concrete raising foam. The cement grout slurry used in Mudjacking comes without the flammability, health risks, higher costs, and other drawbacks associated with poly foam.

Mudjacking has a long, time-proven history of success and is long-lasting, while polyurethane foam’s long-term durability has yet to be proven.

Mudjacking is all-natural and 100% recyclable and comes without the negative environmental impact of poly foam.

A Mudjacking mixture is adjustable onsite. Strength can be increased up to 5000 psi. Versus polyfoam at 100 psi. The mix can be tightened or loosened as needed and is more controllable, leading to a higher job success rate.

Mudjacking will not stain and permanently damage surrounding areas like polyfoam.

Where to Get a Mudjacking Contractor

There are several ways to repair concrete that has settled; the most traditional method of repair is concrete replacement. This method is time-consuming and costly. Surprisingly, most homeowners and businesses are unaware that a Concrete Raising method exists.

To find a concrete leveling contractor in your local area, search for concrete leveling, mud jacking, Concrete Raising, or concrete lifting.

If you need concrete repair in the New Jersey or Eastern Pennsylvania region, check out Our Services at Concrete Chiropractor®. We are “The Trusted Leading Experts in Concrete Raising Since 2000®.” Contact Us for a professional evaluation.

Learn more about Mudjacking and Polyurethane foam concrete leveling methods with these articles from our Learning Center. Our Concrete Chiropractor® informational resource center.

What Is Mudjacking? (History, Process, And Cost)

Does The Weight of Concrete Leveling Material Matter? Why The Experts Say No

Advantages of Mudjacking for Use in Slab Leveling

- Garage Floor Raising and Coating: The Ultimate Guide - June 4, 2024

- Mudjacking Cost: 5 Factors That Affect It - April 10, 2024

- What is The Average Cost of Concrete Leveling in Belle Mead, NJ? - April 4, 2024