IN THIS ARTICLE

Our team at Concrete Chiropractor has dedicated over forty years to concrete installation, replacement, and repair. We have been raising concrete since 2000.

There are two main products used to raise concrete. Cement grout and poly isocyanate, otherwise known as poly foam or poly leveling. While we could easily add poly foam as a concrete raising product, our research convinced us that there was no significant benefit of using poly foam to raise or level concrete and that the product came with associated liabilities, risk and cost to our customers, employees, and environment.

We studied, tested and compared both products and referenced scientific reports and factual information from the Centers for Disease Control, the Occupational Safety and Health Administration, and the New Jersey Institute of Technology. Their reports are based on studies from civil and environmental engineers, chemists, scientists, and medical professionals. You can see the case study here: https://concretechiropractor.com/wp-content/uploads/2021/07/White_Paper_Rev_Jul2021.pdf

While cement has been used for thousands of years and poly foam has been recently introduced, they both will raise concrete. However, we simply do not see poly foam as being beneficial or necessary.

Let us break down and cover the cause of concrete settlement along with the claims and performance of each product.

Cause of Concrete Settlement – Watch Video Here (new window)

During the initial construction of a home, building pool, etc., excavation takes place. After the installation of footings, foundations, or pools, loose soil is then back filled and concrete walkways, patios and floors are installed on the soil surface.

This fill can be a depth of several feet. A depth of six or seven feet is common next to home foundations. As the loosely back filled soil reconsolidates and settles, any concrete, steps, pavers, AC units, or other items installed on the soil surface will sink and settle.

The proper method of backfilling will include placing and mechanically tamping the soils in one-foot layers, but this step is often skipped due to the initial added time and cost. While the cost of proper soil compaction is minimal during initial construction, the long-term cost of replacement can be very costly. The concrete leveling process is a quick and efficient method to restore concrete back to its original height without the need for removal, disposal and re installation.

Product Expansion and Compaction Claims – Watch Video Here (new window)

One claim we often hear from the poly foam industry is that the product will expand into and compact surrounding soils. When cement grout or poly foam is injected under the concrete, it will remain on the top-soil surface and float the concrete back into position. As pointed out previously, the loosely backfilled soil can be a depth of several feet. We consider this claim to be a misrepresentation as either concrete raising product will not reach a depth of the several feet needed to compact loose soils and prevent settlement. It is common for soil reconsolidation and natural compaction takes a period of ten of more years. Neither concrete raising product will reach a depth of several feet to achieve proper compaction.

Product Weight-

The most common claim we hear made by the poly industry is that poly foam is light weight and will not cause further settlement like Mudjacking cement grout. We consider this claim to be a gross misrepresentation based on construction knowledge, soil weight bearing capabilities and facts for the following reasons.

While poly foam is four pounds per cubic foot and cement grout is 100 pounds or more per cubic foot, the average soil bearing capability on undisturbed soils averages 1500 to 3000 pounds per square foot. Therefore, normal soil condition will support between 15 to 30 cubic foot blocks of cement grout.

The average two story home weights between 240,000 and 360,000 pounds and rests on the same soil as your settled concrete. The difference is that the base soils your home is resting on have not been disturbed like the surrounding excavated soils. Once full soil reconsolidation takes place based on the age of initial construction, and once settlement has fully completed, chances of further settlement are reduced. A truthful contractor with proper construction knowledge can evaluate each situation individually.

The fact is concrete raising or concrete replacement will not prevent further settlement, making a honest and proper evaluation the most important part of any concrete leveling repair.

Product Strength – Watch Video Here (new window)

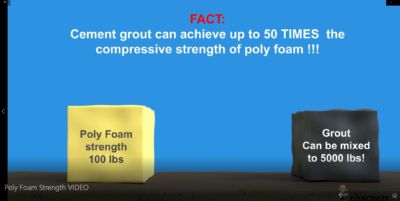

Mudjacking with cement grout has a huge advantage over poly foam when it comes to compressive strength.

Poly isocyanate foam is a two-part product that arrives in separate drums as part A and Part B. These two products are mixed to a set ratio which yields 100 psi. The product cannot be altered to achieve higher compressive strengths onsite.

The specification for a cement grout mix used in Mudjacking is 500 psi., or five times the compressive strength of poly foam. However, the cement ratio can be changed onsite to meet specific requirements to achieve a compressive strength of up to 5000 psi., or fifty times the strength of poly foam.

Product Wash Out- Watch Video Here (new window)

We often hear claims that poly foam will not wash away like mudjacking cement grout. While poly foam is a plastic, we all know that plastics do not break down in water, but our side-by-side water test shows that they do float.

We tested our 500 psi. cement grout in pressurized container with water running on it for a period of one hour and fifteen minutes. Conditions your outdoor soil will never be subject to in normal circumstance. When we removed the two products, the cement grout remained solid and could not be compressed, while the poly foam was spongy, and we were able to compress the product between two fingers.

Do not be fooled by the poly foam contractor who perform this side-by-side test with regular soil. We all know regular soils will disintegrate under water pressure. We welcome any poly foam contractor to do this side-by-side test for the public on camera.

The true concern is if a water problem or poor drainage exists onsite, ALL water problems must be corrected. Regardless of the concrete raising product used, based soils will continue to erode, causing further issue.

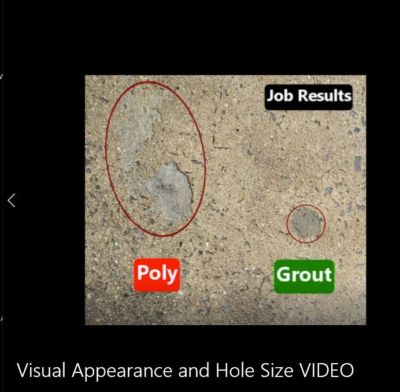

Hole Size-

We have seen gross exaggerations and claims made by the poly industry which claim Mudjacking requires holes up to 3”, or the size of a soda can. Now let us look at the facts.

The Mudjacking process requires a 1” access hole. This is the size of a U.S. quarter, while a poly foam hole is 5/8” of an inch, or the size of a dime. You can see this minimal difference by laying a dime on top of a quarter. While there is this minimal difference in hole size, the visual result in the end can vary based on several factors.

Let’s talk about what effects the result.

Your concrete-

Concrete strengths vary. The standard for older concrete was 3000 psi., while the new standard is 4000 psi. based on Portland cement content. Older, weaker concrete tends to chip a bit more when drilling the surface. This is true for both Mudjacking and poly foam access holes. When patched, the holes will appear larger than the initial drill hole.

The technician-

We have all seen amateur cement repairs. An experienced tradesman has the necessary skills to provide you with the best hole patch appearance over the amateur. We have raised concrete that was previously repaired by poly contractors. When we do a side-by-side comparison, we have seen poly foam drill holes that were smeared and over 3” in comparison to our 1” hole.

Poly foam Staining-

While a cement based mudjacking grout will easily rinse off the surface during initial clean up, the plastic-based poly foam can stick to the concrete surface and leave permanent staining. We have also seen cases where the material had splashed on siding, doors, and other items.

Product Flammability, Toxicity, and Reactivity- Watch Video Here (new window)

All products are required to have a material safety data sheet, or MSDS sheet. This is public information, and you can request these sheets from your contractor. So, let us compare the two products.

Concrete leveling cement grout is derived from locally available, earth materials such as sand, clay, and Portland cement. The safety equipment required is an N95 dust mask and gloves when mixing the product. There is no direct risk to the customer.

Poly isocyanate, or poly foam, is a petroleum-based product derived from crude oil. It is highly reactive and flammable. There are documented cases of the product generating heat when mixed, resulting in self-combustion where the product had burst into flames. This has led to health-related lawsuits from and claims of “neurological injuries, cognitive deficits, dizziness and blurred vision, weakness and fatigue, depression and chronic pain.”

There is also a product toxicity factor. The product off gases and has resulted in exposure sensitivity and death according to reports by the Centers for Disease Control and the National Institute of Safety and Health. “Workers exposed to diisocyanatos may develop serious or fatal respiratory disease” as severe asthma and deaths from exposure and sensitization to the product have been reported.

The Occupational Safety and Health Administration states “isocyanates include compounds classified as potential human carcinogens are known to cause cancer in animals.” NIOSH lists the following personal protection equipment when installing the product. A respirator, full skin and body protection, nitrile gloves, and eye protection or a face shield.

NIOSH also states that… “A medical monitoring program should be established for the early detection and prevention of the acute and chronic exposure to isocyanates. The worker’s physician should be given information about the adverse health effects of exposure to isocyanates and the worker’s potential for exposure.”

Negative Environmental Impact – Watch Video Here (new window)

While we are all aware of the recent bans of plastic bags, Styrofoam containers, and other single use plastics that have negatively impacted our environment, poly foam plastics come with the same concerns.

Poly foam is a petroleum-based product derived from crude oil. The product is then transferred to refineries. After the product if refined, it is transferred to a warehouse facility. Then transferred to the poly foam installation contractor. This transfer process can be thousands of miles, leaving a carbon footprint from exhaust emissions.

Poly foam is then injected under the concrete until the concrete will need replacement at some point. When the concrete is broken and removed, it is brought to a recycling facility where is it crushed and sold to be reused as a base material for new construction. But not the poly foam.

Concrete recycling facilities consider poly isocyanate foam a contaminant which they do not accept. At an added cost to the consumer, the sticky poly foam substance must be separated and remove from the concrete and disposed of at a landfill for a higher disposal cost than concrete. This also comes at an additional labor cost.

Final Product Comparison and Assessment-

We have questioned the addition of the poly foam concrete raising product and what we consider marketing misrepresentations by the poly foam industry. We see poly foam offering the following benefits to the manufacturers and distributors over a cement grout as a concrete raising solution:

Poly Foam Product Control-

While cement grouts are less expensive locally available, poly foams are manufactured by chemical companies, then sold by distributors. This allows these companies to maintain ongoing profit from the contractors continued use and dependency on the poly foam product. Poly foam products on average are three times the cost of cement grouts.

Poly Foam Installation Equipment-

While Mudjacking equipment typically requires a larger tow vehicle or truck and material storage yard, poly foam equipment such as trailer packages allow contractors to enter the concrete raising field at an initial lower cost. But that is where the savings ends. Any initial startup costs will be quickly offset by continued use and dependency of the poly foam products.

Poly foam installation equipment also allows manufactures to build a steady customer base of contractors who rely on equipment upgrades and parts.

While poly foam is a new product compared to cement products which have a time proven use dating back thousands of years. When we compare the two products based on construction knowledge and facts, along with product strength, health and liability risks, and the end cost to the consumer and our environment, we consider the use of poly foam in the concrete raising process to offer no additional benefit. We consider using the product to be an irresponsible choice.

- Garage Floor Raising and Coating: The Ultimate Guide - June 4, 2024

- Mudjacking Cost: 5 Factors That Affect It - April 10, 2024

- What is The Average Cost of Concrete Leveling in Belle Mead, NJ? - April 4, 2024