IN THIS ARTICLE

Introduction

Concrete, known for its durability and strength, is a widely used construction material. Over time, concrete slabs may develop cracks in driveways and sidewalks due to shrinkage, settlement, traffic, or harsh weather. This article will explore the causes and types of concrete cracks and discuss practical concrete repair methods for preventing further damage.

Causes of Concrete Cracks

- Shrinkage Cracks:

Shrinkage cracks are common in concrete and typically result from the natural drying and curing process. As water in the concrete mixture evaporates, the concrete shrinks, developing small, fine cracks. While these cracks are generally superficial, they can be unsightly and may allow water to penetrate the concrete. - Settlement Cracks:

Settlement cracks occur when the underlying soil beneath a concrete structure sinks or shifts, causing the concrete to settle unevenly. This type of crack is often more significant and may indicate a problem with the supporting soil. Addressing the underlying soil issues is crucial when dealing with settlement cracks. - Temperature-Related Cracks:

Extreme temperature fluctuations, especially freeze-thaw cycles, can cause concrete to expand and contract, leading to temperature-related cracks. These cracks are more likely to occur in regions with harsh winters, where the repeated freeze and thaw cycles can weaken the concrete over time. - Structural Overload:

Excessive loads or structural stress can result in cracks in concrete. Heavy traffic loads, overloading of floors or slabs, or the settlement of adjacent structures can cause this. Understanding and addressing the structural requirements of a concrete element are crucial to preventing these types of cracks. - Corrosion of Reinforcement:

If the reinforcing steel within the concrete corrodes, it can lead to the development of cracks. Corrosion is often a result of exposure to aggressive chemicals, salt, or environmental conditions that compromise the protective layer around the reinforcement. Regular maintenance and proper protective measures can help prevent corrosion-related cracks.

Types of Concrete Cracks

- Hairline Cracks:

Hairline cracks are thin, superficial cracks common in most concrete structures. While they may not pose an immediate structural threat, they can allow water penetration and, over time, may lead to more significant issues if left unaddressed. - Map Cracks:

Map cracks are a network of interconnected cracks resembling a map pattern. These cracks are often caused by drying, shrinkage, or thin and poorly designed concrete. The cracks can be more pronounced in larger concrete slabs. Proper joint placement, concrete thickness, reinforcement, and curing techniques can help minimize the occurrence of map cracks. - Settlement Cracks:

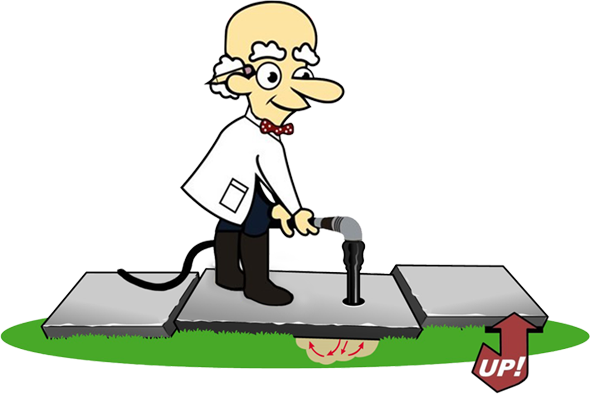

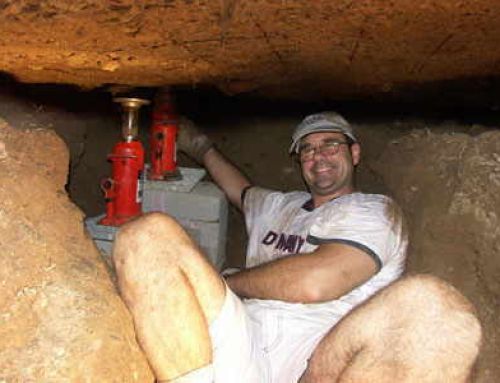

Settlement cracks are typically wider and more severe than hairline cracks. These cracks often indicate underlying soil issues that must be addressed to prevent further settlement and structural damage. When there is limited damage or cracking, concrete leveling is a method of repair where concrete settlement can be corrected through the injection of cement slurry grout known as mudjacking, or polyurethane injection with a process known as concrete poly leveling. - Expansion Cracks:

Expansion cracks occur when concrete expands due to temperature changes or other factors and has insufficient space to accommodate the expansion. These cracks are more likely to occur in large concrete slabs that lack proper expansion joint placement, making concrete floor crack repair necessary.

Methods of Concrete Crack Repair

Before selecting a concrete crack repair method to fix cracks, it is necessary to categorize whether you are repairing indoor or outdoor concrete and whether it will be subject to frost movement. Indoor concrete is not subject to movement from freezing temperatures, or forklift traffic with warehouse concrete floor repair can be repaired with non-flexible cement and epoxy products. Concrete cracks subject to movement require a flexible product applied with a caulk gun to avoid further failure.

- Epoxy Injection:

Epoxy injection is a widely used method for repairing cracks in concrete structures. This technique involves injecting a low-viscosity epoxy resin which fills cracks, effectively bonding and sealing them. Epoxy injection is particularly effective for structural cracks and can restore the concrete’s integrity. - Polyurea Injection:

Like epoxy injection, polyurea injection involves injecting a flexible polyurethane resin into cracks to seal and waterproof them. Polyurea is especially useful for sealing “indoor” cracks in concrete that may experience movement, as it remains flexible after curing. - Concrete Resurfacing:

Concrete resurfacing is an effective solution for cosmetic or surface-level cracks. This involves applying a thin layer of new concrete patching materials over the existing surface, covering minor cracks, and providing a fresh, uniform appearance. Resurfacing is a cost-effective way to enhance the aesthetic appeal of concrete.

Before resurfacing concrete, it is essential to establish that the cracks are not at full depth and that the concrete will not be subject to movement from frost. Resurfacing over concrete cracks prone to movement will cause the crack to reappear on the surface of the coated concrete. - Crack Routing and Sealing:

When cracks are wider or up to an inch wide, a common technique is to make them bigger before sealing them. You can use special tools such as a hand grinder and diamond blade. These tools are used to remove loose dirt and open the crack. By doing this, the sealant can stick better. After routing, the crack is filled with a backer rod or sand, along with a suitable sealant to prevent further water infiltration. - Carbon Fiber Stitching or Reinforcement:

Carbon fiber reinforcement can strengthen and stabilize the affected areas when cracks indicate structural issues. For carbon fiber stitching, saw cuts are made across the crack, and a carbon fiber strip or bar is epoxied into the cut. Carbon fiber strips are sometimes applied over the cracked surface and bonded with a high-strength epoxy, providing additional support and preventing further movement. - Joint and Crack Fillers:

Joint and crack fillers, such as silicone or polyurethane sealants, are commonly used for sealing small to moderate cracks. These flexible sealants are recommended for outdoor concrete cracks that are subject to frost and will accommodate slight movements in the concrete and prevent water penetration. Proper joint design and maintenance are crucial for the effectiveness of these fillers.

These concrete caulks or fillers come in solid colors and can be very noticeable. Sand that is closer in color to the concrete surface can be broadcast into the surface of the sealer when placed to help offset the color difference.

Prevention Strategies

- Proper Mix Design and Curing:

Ensuring the correct mix design and following proper curing practices during concrete placement can significantly reduce the occurrence of cracks. Adequate water-to-cement ratio, the use of quality aggregates, and proper curing techniques contribute to the overall durability of concrete.Proper concrete thickness is also necessary. Thin or under-designed concrete has a higher likelihood of failure. While a thickness of 4” is sufficient for foot traffic, 6” is recommended for areas subject to standard vehicle traffic. Concrete slabs exposed to truck traffic must be designed for their specific application and are often thicker. - Control Joints:

Installing control joints, also known as expansion joints, at strategic locations in concrete structures helps control the natural shrinkage and expansion of the material. These joints provide a designated space for concrete to crack, reducing the likelihood of uncontrolled and unsightly cracks.Control joints are cut into the concrete to control cracking, while expansion joints are installed during initial placement. The spacing and placement of joints are determined by the thickness and design of the slab. This is done to prevent the formation of large or unevenly shaped slabs.These slabs are likely to crack. Expansion joints are placed against masonry walls or adjoining concrete to separate the new concrete installations and allow for movement. - Reinforcement and Structural Design:

Proper structural design, including reinforcing steel, wire mesh, or fiber, can enhance concrete structures’ overall strength and load-bearing capacity. Adequate reinforcement helps distribute loads and minimizes the risk of cracks due to excessive stress. - Regular Maintenance:

Regular inspections and maintenance are crucial for identifying and addressing potential issues before they escalate. Prompt repair of minor cracks prevents them from becoming major structural concerns. When cracks remain open, de-icing agents can lay in the crack and cause deterioration of the slab. - Waterproofing:

Applying waterproof coatings or sealers to the surface of concrete structures helps protect against water infiltration and damage from de-icing agents, reducing the risk of cracks caused by freeze-thaw cycles or corrosion of reinforcement.

Conclusion

Concrete crack repair is a multifaceted process that requires a thorough understanding of the causes and types of cracks and the appropriate repair methods. Whether dealing with hairline cracks, settlement cracks, or more significant structural issues, choosing the correct repair technique is essential to ensure the longevity and integrity of concrete structures.

Some small cracks in concrete can be left alone and won’t cause more damage for many years. Small cracks in concrete can be left alone without causing further damage for many years. However, it is advisable to take preventive measures, use good construction techniques, and promptly fix cracks with appropriate repairs.

These actions can help extend the lifespan of concrete slabs and structures while also improving their appearance. Regular maintenance, vigilant monitoring, and collaboration with qualified professionals have been crucial in preserving concrete’s strength and aesthetic appeal for years.

Concrete Chiropractor® offers Mudjacking Services throughout the New Jersey and Eastern PA areas of Bucks County, Northampton County, and Lehigh County. If you are developing concrete cracks due to concrete settlement, contact us for a professional evaluation from our seasoned experts.

You can also visit our learning center and view some of these related articles along with other information:

What is Mud Jacking? (History, Process, and Cost)

DIY Concrete Repair Videos

Why Repairing Your Own Cracked Concrete Can Cost More Money

- Garage Floor Raising and Coating: The Ultimate Guide - June 4, 2024

- Mudjacking Cost: 5 Factors That Affect It - April 10, 2024

- What is The Average Cost of Concrete Leveling in Belle Mead, NJ? - April 4, 2024