IN THIS ARTICLE

While concrete floors in warehouses, production facilities, and distribution centers are subject to the heavy damage due to forklift traffic, all commercial floors will need maintenance at some point.

Safety is the number one reason for most concrete floor repairs. Often, damage will occur at a construction joint location and will usually get progressively worse. The failure will then continue it’s way outward. When this occurs, it becomes costly, slowing production. Forklift operators need to slow down while passing over the damaged area, to avoid a safety issue or material loss. This can also result in serious injury to operator, or other employees.

Damage to concrete floors in retail establishments can also be problematic. Chipped or missing joints allow for a hazardous walking surface in which thin heeled shoes can get caught. This can also present a problem for floor maintenance such as when washing or polishing the surface.

Concrete floors in pharmaceutical and food storage facilities generally must meet FDA requirements regarding bacteria growth and cleanliness. Joints that have been neglected, along with other damaged areas become problematic while maintaining sanitary conditions, such as with floor scrubbers.

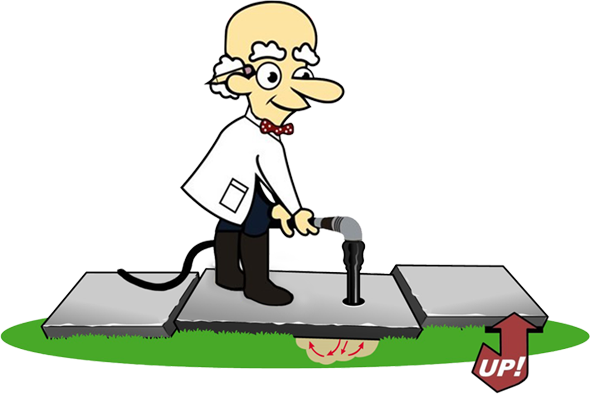

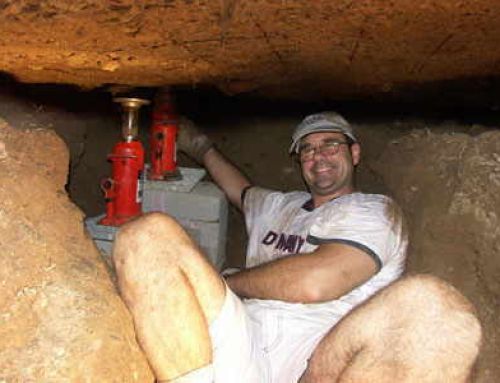

The first step in commercial or industrial concrete floor repair is a proper assessment regarding the cause of failure. If the cause is not resolved during the repair process, further damage will continue. For instance, if there is floor movement, the movement must be stabilized prior to any surface repair. Unsupported base issues must be corrected. Once the initial evaluation has been completed, there are several methods of repair depending on floor traffic, company needs, and proper product application. These products can include cementitious products, sold by high quality manufacturers, such as Ardex or Sika. There are also a variety of epoxy-based repair products from Metzger McGuire, a leading supplier in commercial concrete floor repair. A major determining factor in product choice is down time. Most facilities have a limited window of opportunity to get in and complete the repair in the fastest time possible. Often, the repair may be subject to forklift traffic in just a few hours.

Repair methods can vary from light maintenance, such of joint clean out and resealing, to sectional cut outs that require full depth replacement of the concrete. One common repair is referred to as a joint rebuild. A joint rebuild entails saw cutting both sided of a control joint to create square, solid edges. The damaged concrete is then removed between a half inch and two inches in depth. The joint is then rebuilt with a proper high strength repair product. Depending on the flexibility of the product used, the joint may be saw cut open and sealed with a semi-rigid joint sealant to provide flexibility and protect the edges from chipping and damage.

While the initial cost of hiring a knowledgeable, experienced, professional company to complete these complex floor repairs are higher, the long-term cost of amateur work far exceeds that of a well done, professional repair. When taking the overall costs into consideration, such as operational down time, in addition to the cost of having to repeat any repair a second or third time, choosing a contractor based on cost can be the most expensive choice one can make. Concrete Chiropractor® offers you over four decades of concrete repair experience and knowledge, combined with the use of the highest quality, well known products on the market.

- Garage Floor Raising and Coating: The Ultimate Guide - June 4, 2024

- Mudjacking Cost: 5 Factors That Affect It - April 10, 2024

- What is The Average Cost of Concrete Leveling in Belle Mead, NJ? - April 4, 2024