IN THIS ARTICLE

Concrete floor leveling involves processes used to correct uneven or sloping concrete floors. It involves techniques that restore the surface to a level and flat condition. Here’s a general overview of how concrete floor leveling works:

1. Assessment: The first step is to assess the condition of the concrete floor. A professional will inspect the floor for any cracks, low spots, or areas of unevenness. They will also identify the underlying cause of the problem, such as soil settlement or inadequate subfloor preparation.

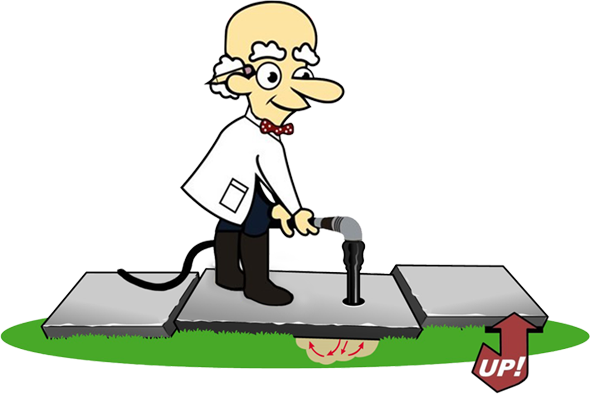

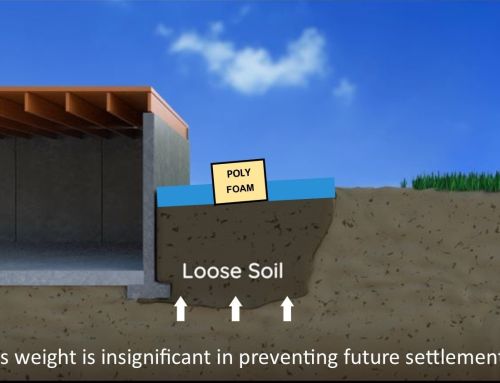

2. If concrete floor settlement or sinking has occurred, a method known as concrete leveling or Mudjacking is required to support the concrete floor to avoid further settlement. Self-leveling cement should “never” be applied to an unsupported concrete floor surface as further floor settlement and product failure is likely to occur.

3. Surface Preparation: Before leveling the floor, the surface needs to be properly prepared. This typically involves cleaning the floor to remove any dirt, debris, or loose material. If there are any cracks or gaps, they may be filled with an appropriate filler or patching compound.

4. Leveling Compound: A self-leveling compound is commonly used to level the concrete floor. This compound is a liquid mixture that spreads across the floor and seeks its own level. It is made up of cement, fine aggregates, and additives that help it flow and self-level. The compound is poured onto the floor and spread out using a gauge rake or a squeegee.

5. Spreading and Smoothing: Once the self-leveling compound is poured, it needs to be spread evenly across the surface. A smoothing tool, such as a long-handled squeegee or a trowel, is used to push and pull the compound, ensuring it fills low spots and creates a level surface. The compound is typically self-leveling, so it will seek its own level and flow into low areas.

6. Curing and Drying: After the compound is spread and smoothed, it needs time to cure and dry. The specific drying time will depend on the type of leveling compound used and environmental conditions. It’s important to follow the manufacturer’s instructions regarding curing and drying times to allow the compound to set properly.

7. Finishing: Once the leveling compound is fully cured and dried, the surface can be further finished if desired. This may involve sanding or polishing the surface to achieve a smooth and uniform appearance.

It’s worth noting that the process may vary depending on the specific leveling technique or product used. For example, some cases may require more extensive floor preparation, such as grinding or shot blasting, to create a suitable surface for leveling. Additionally, in situations where the floor has significant damage or structural issues, additional steps may be necessary, such as concrete repairs or reinforcement.

It’s recommended to consult with a professional concrete contractor who specializes in floor leveling to assess your specific situation and determine the most appropriate leveling method for your needs.

- Garage Floor Raising and Coating: The Ultimate Guide - June 4, 2024

- Mudjacking Cost: 5 Factors That Affect It - April 10, 2024

- What is The Average Cost of Concrete Leveling in Belle Mead, NJ? - April 4, 2024