IN THIS ARTICLE

Uneven sidewalks not only detract from the aesthetic appeal of a property but also pose significant safety hazards. Property owners are responsible for maintaining public sidewalks in many jurisdictions, making it crucial to address any unevenness promptly. This comprehensive guide will explore proven methods for repairing uneven sidewalks.

Concrete Grinding: A Cost-Effective Solution

Concrete grinding is a practical and cost-effective solution to fix sidewalk minor unevenness, typically less than 1.5 inches in difference. This method involves shaving down lifted portions of slabs, effectively leveling the surface, and minimizing trip hazards.

Concrete grinding is a straightforward and affordable process. However, it has a downside.

It can cause the slab to become thinner and more susceptible to cracking. Additionally, it can also lead to damage from freezing and thawing. This option is most suitable for areas where aesthetics is not a primary concern.

For small sidewalk joints, you can use a handheld grinder. However, for larger sidewalk grinding jobs, hiring professionals with the appropriate tools is recommended. Here is how DIY sidewalk grinding is done:

- Gather the Necessary Tools and Equipment:

- Handheld grinder

- Diamond grinding wheel or abrasive stones suitable for concrete

- Dust mask

- Safety glasses

- Ear protection

- Gloves

- Knee pads

- Broom or vacuum for cleaning up dust

- Assess the Sidewalk:

- Inspect the sidewalk for raised edges, cracks, or uneven areas. Mark the areas that need grinding.

- Start Grinding:

- Begin grinding at one end of the sidewalk joint and work your way systematically to the other end.

- Move the grinder in a back-and-forth or circular motion to ensure even grinding.

- Overlap each pass to avoid leaving unprocessed areas.

- Keep the Grinder Moving:

- Avoid stopping in one spot for too long, as this can create uneven surfaces.

- Periodically stop and inspect the ground surface to ensure you achieve the desired level and smoothness.

- You might have to use the grinder several times on the sidewalk to get the desired outcome.

Concrete grinding is dusty and noisy, so protect yourself and the environment with precautions. If you’re unsure or if the job is large, it’s advisable to seek advice from experts or hire experienced contractors. These professionals specialize in concrete grinding.

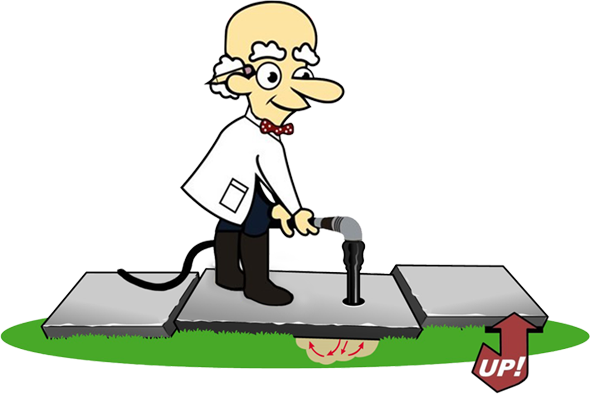

Concrete Leveling: Swift and Effective

Concrete leveling is a highly effective method for fixing sunken sidewalks. This process involves lifting settled slabs from the bottom up, and the entire operation can be completed in just a few hours. There are three main types of concrete leveling:

- Mudjacking: Mudjacking involves injecting an environmentally friendly cement grout mix of sand, soil, water, and cement beneath the slab to lift it.

- Polyjacking (Foam Concrete Leveling): Involves injecting a petroleum-based, two-part expanding polyurethane foam chemical known as diisocyanate under sunken slabs, lifting the concrete back to its original position.

While both methods have pros and cons, using polyurethane foam has been associated with higher product costs and recycling costs for the homeowner, should the concrete ever need replacement. Polyjacking also has a history of toxicity and flammability. These two concrete lifting repair processes require specialized equipment and experience and are best left to the professionals. You can find a local professional by searching for a “concrete leveling contractor near me.”

Adding Extra Concrete: A Temporary Fix

Adding extra concrete or patching compound is an option for a quick and cost-effective solution, especially for more minor trip hazards. However, it’s essential to recognize that this method is often temporary, as the new compound may struggle to bond completely with the existing slab, leading to potential chipping and cracking. If you decide to do a DIY sidewalk patch as a method of sidewalk repair, here is a step-by-step guide:

Materials and Tools:

- Safety Gear:

- Gloves

- Safety glasses

- Dust mask

- Tools:

- Chisel and hammer or a concrete saw

- Wire brush

- Broom

- Pressure washer

- Concrete patch mortar product (without stone) with bonding agents for adhesion

- Trowel and edging tool

- Wooden float or sponge

Preparation:

Wear safety gear to protect yourself from dust and debris. Also, make sure the weather is suitable for the repair. Avoid extremely hot or cold conditions.

Clean the Area:

- Remove loose or deteriorated concrete using a chisel, hammer, or concrete saw.

- Use a wire brush to clean the area thoroughly.

- Rinse the area with a pressure washer to remove any remaining debris and let dry with no standing water.

Patching:

- Mixing the Concrete Patch:

- Follow the manufacturer’s instructions for mixing the concrete. Repeat: Use a mix with bonding agents for better adhesion.

- Moistening the Area:

- Dampen the repair area with water to surface saturated dry (no standing water). This helps prevent the existing concrete from absorbing water from the new mix too quickly.

- Applying the Concrete:

- Mix a slurry of the cement product and scrub a coat into the concrete repair area to help the patch adhere.

- Maintain all sidewalk joints with a piece of wood or expansion joint. Do not “bridge” the concrete repair from one slab to another, as slab movement will cause the patch to fail.

- Use a trowel to apply the mixed concrete to the damaged area. Ensure it is level with the surrounding concrete. Edge the patch once it is firm enough.

- Smoothing and Shaping:

- Once the patch is firm but not hard, use a wooden float or damp sponge to smooth the surface of the patch.

- Reshape the edges with an edging tool to match the surrounding concrete.

- Curing:

- In warm temperatures, cover the patch with a damp cloth or use curing compounds per product instructions.

Following these steps and using quality materials can create a long-lasting sidewalk cement patch repair. Keep in mind that proper preparation, application, and curing are crucial for the durability of the repair.

Concrete Sidewalk Replacement: Comprehensive Yet Expensive

Concrete replacement is the most comprehensive and expensive solution for uneven sidewalks. This approach is warranted in cases where slabs are severely cracked or crumbling or substantial changes to the sidewalk’s shape or functionality are desired. Factors such as tree roots lifting slabs too far out of place may also necessitate complete replacement. Despite its effectiveness, concrete replacement comes with risks, including potential issues with concrete batches and disruption to lawns and landscaping.

Tips for Maintaining Uneven Sidewalk Slabs:

- Trees Next to Sidewalks: Avoid planting trees near sidewalks as their roots can grow and damage the sidewalk. Use root barriers when planting.

- Flexible Concrete Caulk: Use flexible concrete caulk for large concrete cracks or open joints to prevent water seepage under the sidewalk, reducing the risk of settling and damage due to freeze-thaw cycles.

- Eliminate Erosion Sources: Address water flow issues from downspouts, leaky gutters, and poor drainage to prevent soil erosion that can lead to uneven sidewalks.

When to Call a Professional to Fix Your Uneven Sidewalk:

You can do some repairs, like grinding and adding concrete, by yourself. But concrete leveling and replacing concrete should be done by professionals. Concrete Chiropractor specializes in concrete leveling in New Jersey and Eastern Pennsylvania, providing expertise and specialized equipment to ensure effective, long-lasting solutions. Concrete Chiropractor provides evaluations and cost estimates, helping property owners choose the best method for their needs.

Conclusion:

Maintaining safe and even sidewalks is a matter of aesthetic concern and a legal responsibility for property owners. Concrete Chiropractor’s sidewalk leveling tips and information provide practical methods to address uneven sidewalks, considering cost, speed, and long-term durability. Property owners can enhance safety and improve the appearance of their property by selecting the appropriate solution for their specific requirements. These solutions may include concrete grinding, leveling, adding concrete, or completely replacing it.

Click Here to Contact Your Location and Receive a Professional Sidewalk Evaluation Or for more information, visit some of these related articles at our Learning Center.

- Garage Floor Raising and Coating: The Ultimate Guide - June 4, 2024

- Mudjacking Cost: 5 Factors That Affect It - April 10, 2024

- What is The Average Cost of Concrete Leveling in Belle Mead, NJ? - April 4, 2024