IN THIS ARTICLE

Learn why concrete leveling material weight really doesn’t matter during concrete leveling.

When it comes to concrete leveling, one might assume that the weight of the material plays a vital role in ensuring stability and performance. However, in practice, the weight is largely irrelevant. The primary goal is to fill voids and stabilize the existing structure, and modern materials are designed to accomplish this regardless of their weight.

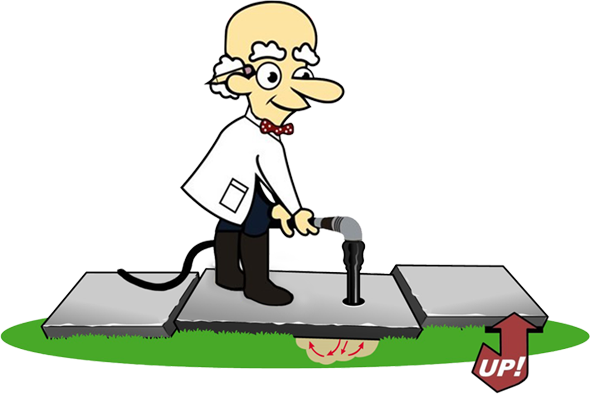

Concrete leveling repairs, whether done using the well-known mudjacking method with cement or the recent process using lightweight polyurethane foam, have been shown to stand the test of time. So, what is all the hype over which concrete leveling method or material is better? Let’s have a look.

“The polyjacking salesman told me that unless I use foam, the mudjacking material is heavy and will cause the concrete to resettle! “

That makes sense.

Wrong!

We have customers with 25-year-old concrete leveling repairs that are still in place today!

At Concrete Chiropractor, we have worked with both poly foam and mudjacking. With nearly 25 years in the industry, our on-the-job experience and structural engineer reports have shown that although concrete leveling material weight is being used as a marketing tool to sway customers, it really does not matter.

Concrete Lifting Material Weight. Fact Versus Fiction

What is The Cause of Concrete Settlement

The first and foremost factor to consider is what causes concrete settlement.

The leading cause of concrete settlement is soil disturbance during initial construction in and around a home or building. These areas include concrete pool decks, patios, garage floors, sidewalks, porch tops, driveways, floors in homes, and warehouse floors.

The first step during construction is soil excavation. Once the structure or inground pool is built, these excavated soils are used to backfill and grade around the newly constructed project. The depth of the soil disturbance can vary, with areas closest to a basement foundation wall reaching depths of seven feet or more.

Proper soil compaction practices are often overlooked, followed by concrete being placed on the surface. As soil reconsolidates and settles, so does the concrete. While it is impossible to predict how long the soil settlement process will take, an average estimate is 5 to 10 years, depending on depth.

In this video by Concrete Chiropractor, you can see what causes sinking concrete:

Fact: Injecting lightweight concrete leveling foam under a concrete slab and onto base soil that has not yet finished settling will leave you with a settled slab with lightweight foam underneath it!

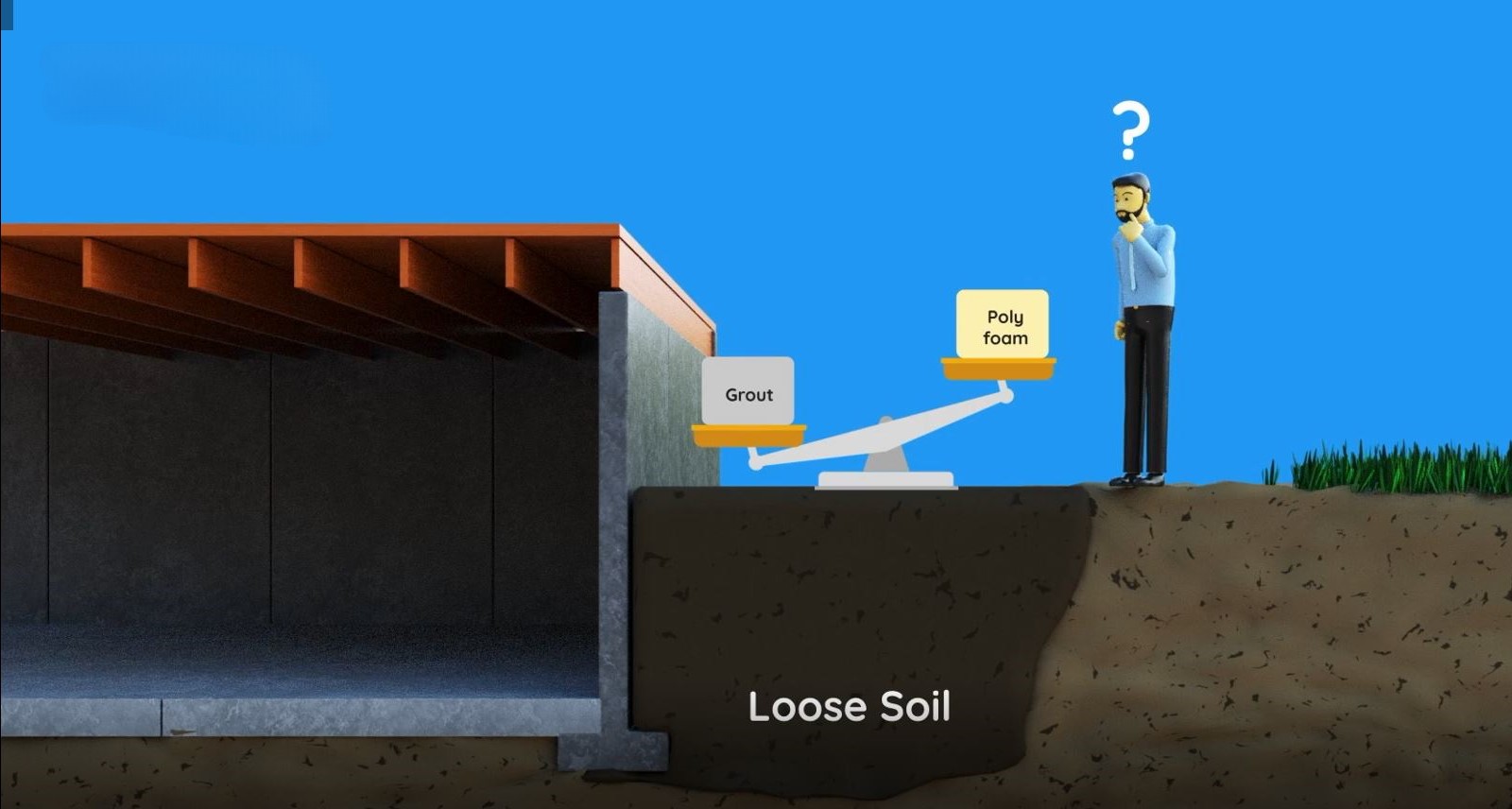

“I heard Poly Foam Only weighs 4 Pounds Per Cubic Foot, and Mudjacking grout is 150.”

While this comparison sounds significant, it does not hold weight. No pun intended!

Concrete or mudjacking grout weighs 50 pounds per cubic foot at 4” thick, while the polyfoam weighs less than a pound. But the average soil-bearing capacity of consolidated soil is a whopping 1500 to 3000 pounds per square foot!

This means that mudjacking grout or poly foam is less than 5% of what the average soil will support per square foot.

Fact: Concrete leveling material weight differences are not a significant factor. The weight of your entire home is resting on the soil!

What DOES Matter Regarding Concrete Leveling Material?

Long-term Durability

In concrete leveling, long-term durability is a key consideration over the weight of the materials used. A durable leveling job extends the life of your concrete surfaces and reduces the need for future repairs, ultimately saving time and money.

Concrete leveling compounds and mudjacking methods offer strong durability by adhering seamlessly to existing slabs and filling voids beneath them. These techniques reduce the likelihood of further settlement issues. They are designed to withstand the rigors of daily use, whether it’s a high-traffic driveway or a less demanding basement floor.

By focusing on durability rather than weight, you ensure that the materials chosen support the current need and provide a lasting solution.

Material Strength

Polyjacking foam is lighter than mudjacking cement grout. It only has 1/5th of the strength at 80-100 psi. The minimum mudjacking mix design is 500 psi.

Poly foam cannot achieve higher strength while mudjacking grout strength can be increased on demand up to 5000 psi, or TEN TIMES the strength of foam.

Proper Void Fill

Filling all the voids under concrete slabs provides full support and a strong foundation, preventing the concrete from bridging or resting on only pillars of material, which can eventually cause the concrete slab to crack.

Concrete Chiropractor’s mudjacking process with cement grout flows over distance, raising and supporting your concrete slab and restoring long-term stability.

Cost-Effectiveness

Cost-effectiveness is a significant factor when choosing materials for concrete leveling. It often determines the project’s feasibility and the financial impact on property owners. By selecting cost-effective materials, you balance upfront expenses with long-term benefits, ensuring you get the best value for your investment.

Traditional mudjacking remains one of the most affordable and reliable leveling methods available. Its use of locally sourced, natural materials helps lower material costs, and the process itself is efficient and proven to deliver long-term performance.

Self-leveling cement compounds are another budget-friendly option, particularly for large interior surfaces like warehouse floors or garages. These compounds require less labor and set quickly, minimizing project downtime and labor costs.

By investing in higher-quality, cost-effective materials, you achieve a balance of affordability and durability, ensuring a smart investment in concrete leveling.

Health and Environmental Safety

Mudjacking grout is a mixture of sand and locally sourced earth materials mixed with Portland cement. It is all-natural and 100% recyclable when attached to the existing concrete.

Polyfoam, also known as polyisocyanate, is a two-part chemical product derived from crude oil. It is toxic and flammable and has a history of self-combustion during installation. Concrete recycling facilities do not accept the product, so it must be removed from the concrete and brought to a landfill. This leads to a higher disposal cost to the homeowner and a long-term environmental impact.

This video by Concrete Chiropractor shows the concerns with poly foam flammability:

Concrete Maintenance

With concrete leveling or mudjacking grout, if the soil base beneath the two products erodes from drainage issues, this can cause concrete settlement.

Maintain your gutters and downspouts. Make sure your gutters are not clogged and that downspouts are diverted far enough away from your concrete. Also, take care of any yard drainage issues.

Taking the proper steps to prevent erosion will help your concrete last a lifetime.

Your choice of Contractor

Be sure to choose a quality contractor. Check their history by checking how long they have been in business, their reviews, what type of warranty they offer, and if there has been any negative feedback when honoring their warranty.

A reputable contractor understands the importance of maintaining positive customer relations as part of their long-term business plan.

What’s Next

Now that you know why concrete leveling material weight really doesn’t matter and can’t be swayed by unsupported claims that heavier material like mudjacking grout will cause your concrete to resettle, you can visit our Learning Center.

There, you can find related concrete leveling articles such as:

Mudjacking Vs. Poly Jacking: Which is The Better Choice

Advantages Of Mudjacking For Use In Slab Leveling

If you want to speak with our Concrete Chiropractor team about your concrete leveling needs, click the link below for an expert evaluation!

Click Here to Receive a FREE Estimate From Your Nearest Location

- How We Raised a Sunken Concrete Walkway in Sewell, NJ - November 20, 2025

- Carbon Fiber Foundation Repair: All You Need to Know - November 20, 2025

- 5 Common Causes of Concrete Porch Collapse (and How to Prevent It) - November 20, 2025