IN THIS ARTICLE

Self-Leveling Concrete: What Works, What Doesn’t, and Smarter Alternatives

Uneven or sloping floors are a common headache for many New Jersey homeowners. Whether it’s a basement slab that dips in one corner, a garage floor with puddling water, or an interior room that feels “off” when you walk across it—these issues are more than cosmetic. They can make flooring installations tricky, cause tripping hazards, and even lower your home’s value.

One solution that many DIYers and contractors consider is self-leveling concrete (SLC). It’s marketed as a quick, easy fix that creates a smooth, flat surface in just a few hours. But here’s the truth: while SLC can be incredibly effective, it’s not a magic solution for every situation.

In this guide, we’ll cover:

- What self-leveling concrete really is and how it works

- The right (and wrong) situations to use it

- Common mistakes homeowners make when applying it

- Alternatives when leveling alone won’t solve the problem

By the end, you’ll know whether self-leveling concrete is the right fix—or if your floor needs a deeper repair like mudjacking before you pour.

What is Self-Leveling Concrete and How It Works

Self-leveling concrete, often called SLC, is a cement-based material designed to create a smooth, flat surface without the need for heavy finishing tools. Unlike traditional concrete that requires troweling, SLC is thinner and flows more easily. Once poured, it spreads out across the surface on its own, filling dips, small depressions, and uneven spots.

The material is usually mixed with water to form a slurry. After mixing, it has a short working time—typically between 10 and 20 minutes—before it begins to harden. Because of this, preparation is just as important as the pour itself. The surface must be clean, free of dust and debris, and usually treated with a primer so the SLC can bond properly.

Self-leveling concrete is commonly used indoors for floors that will later receive finishes like tile, vinyl, laminate, or carpet. It provides a smooth base that prevents gaps under flooring and keeps surfaces even. In some cases, it can also be used to cover radiant heating systems embedded in the floor.

However, it’s important to understand what SLC can and cannot do. It does a good job of fixing minor surface unevenness, but it does not strengthen or stabilize the slab underneath. If the floor is sinking because of soil settlement or voids beneath the concrete, SLC will only mask the problem for a short time. Eventually, the new layer may crack or settle again.

That’s why SLC is best suited for cosmetic fixes and surface preparation—not for addressing structural settlement issues.

Proper Preparation Before Pouring Self-Leveling Concrete

Before using self-leveling concrete, preparation is the most important step. Skipping or rushing this part often leads to failure, such as cracks, peeling, or the layer not bonding correctly.

The first step is to inspect the existing floor. Self-leveling concrete only works on a solid base. If the slab underneath is crumbling, hollow, or settling due to soil movement, applying SLC will not fix the real problem. In those cases, the concrete itself may need repair or replacement before any leveling can be done.

Once you’ve confirmed the slab is sound, the surface must be cleaned thoroughly. Any dirt, grease, dust, or paint will prevent the slurry from bonding properly. Mechanical cleaning, such as grinding or shot blasting, may be needed for older or heavily contaminated slabs. After cleaning, vacuuming is recommended to remove fine particles.

Next, sealing cracks and joints is important. If left open, the liquid SLC can seep through gaps and disappear beneath the slab. Caulking or foam backer rods are often used to block those pathways. This not only saves material but ensures an even layer on top.

A bonding primer is then applied. Primers are designed to improve adhesion between the old slab and the new self-leveling material. Skipping primer is one of the most common reasons SLC applications fail. Some primers also help control how quickly the water in the slurry is absorbed, which improves curing.

Finally, preparation also includes planning for the pour itself. Because SLC sets quickly, you need enough material mixed and ready, with tools on hand to guide the flow into corners and edges. Having a helper can make a big difference.

Good preparation takes more time than the pour, but it determines whether the finished floor is smooth, durable, and ready for whatever flooring comes next.

Applications of Self-Leveling Concrete

Self-leveling concrete (SLC) is widely used because it creates a smooth, flat surface quickly. But it’s important to understand where it works best and what its limits are. This way, you know when it’s the right solution and when another approach might be needed.

One of the most common applications is as an underlayment for finished flooring. Many floor coverings — like vinyl, laminate, tile, and engineered hardwood — require an even base to perform well. Even small dips, humps, or ridges in the slab can cause flooring to buckle, crack, or wear unevenly. A thin layer of self-leveling concrete corrects those irregularities and gives you a solid surface for installation.

SLC is also used to smooth out old or uneven slabs. For example, if you have an older basement floor with surface wear, or a garage slab with slight unevenness, applying self-leveling concrete can restore a flat surface. It’s not meant to fix structural damage, but it does make a floor usable again for interior projects.

Another application is in commercial spaces. Offices, showrooms, and retail stores often need flooring that looks seamless and professional. Since these areas usually get new floor coverings, SLC is a practical way to prepare the base quickly and with minimal downtime.

Finally, some homeowners and businesses leave SLC as the finished surface, sealing it with a durable coating. While this can create a sleek, modern look, it requires proper sealing since self-leveling concrete itself isn’t as durable as traditional structural concrete.

In short, self-leveling concrete is ideal when the problem is surface unevenness, not structural damage. It shines as a preparatory layer that ensures your finished flooring lasts longer and performs the way it should.

Common Mistakes to Avoid with Self-Leveling Concrete

From what we’ve seen over the years, self-leveling concrete (SLC) is one of those products that looks easy on paper but can go wrong quickly if you don’t know the details. Many homeowners and even contractors make mistakes that lead to wasted material, uneven surfaces, or floors that don’t last. By pointing out the most common errors, we hope to save you time, money, and frustration.

- Poor surface preparation

The biggest mistake is skipping the prep work. SLC does not bond well to dusty, greasy, or flaky surfaces. If you pour it on top of dirt or loose concrete, it will peel up or crack. You need a clean, solid, and properly primed base. We always stress that surface preparation is just as important as the pour itself. - Ignoring primer

Some think primer is optional, but it isn’t. Primer helps the SLC grip the slab and prevents air bubbles from rising through the mix. Without it, you may get pinholes, weak spots, or delamination. - Working too slowly

SLC sets fast. If you mix one bag at a time or try to spread it carefully like regular concrete, it will harden before you’re finished. The result is ridges, bumps, and cold joints. The right way is to mix multiple bags at once and pour them quickly so the material flows together. - Pouring too thin or too thick

Every product has a recommended thickness. Too thin and it won’t bond well. Too thick and it may crack or not cure properly. We see this mistake often when people try to “fix” major dips with SLC instead of addressing the underlying problem. - Using it where it doesn’t belong

Self-leveling concrete is not meant to replace structural repairs. If your slab is badly cracked, sinking, or deteriorated, SLC won’t solve the issue. In those cases, replacement or mudjacking may be the better path.

When Not to Use Self-Leveling Concrete

While self-leveling concrete (SLC) is a useful tool for creating a smooth, even surface, it’s not always the right solution. Knowing when not to use it can save you from wasted effort and money. Over the years, we’ve seen situations where SLC was poured as a quick fix, only to fail because the underlying problem was ignored.

- Severely damaged or crumbling concrete

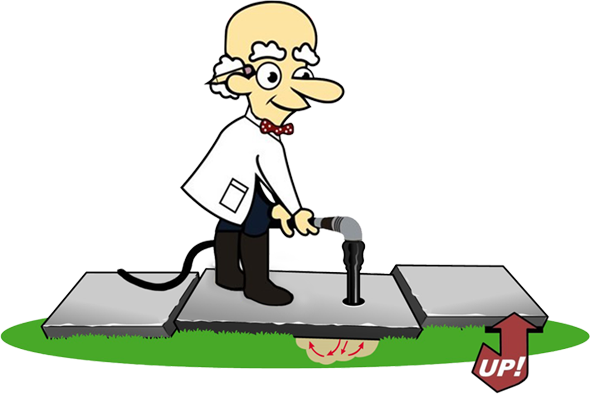

If your existing slab is badly cracked, spalling, or breaking apart, pouring SLC over it won’t stop the deterioration. The new layer will simply mirror the damage underneath and eventually crack too. In these cases, replacing the slab or exploring concrete raising options may be necessary. - Structural or sinking slabs

SLC is designed to smooth out minor unevenness, not to correct sinking or shifting slabs. If your concrete is settling due to soil movement, voids, or poor drainage, pouring SLC won’t address the root cause. In fact, it may add unnecessary weight, making the problem worse. For sinking or unlevel slabs, mudjacking or replacement is the better choice. - Outdoor or high-moisture areas

Most self-leveling products are not designed to withstand constant exposure to rain, freezing, or ground moisture. Using them outdoors, in garages, or in basements with water problems can lead to cracking and delamination. In these areas, you need solutions that are built to handle moisture and temperature changes. - Quick “patch jobs” on major dips

Some people try to fill large voids or dips with SLC as a shortcut. However, if the thickness required is greater than the product’s limit, the pour won’t perform as expected. For deeper issues, replacement is the safer option.

When Self-Leveling Concrete Wasn’t the Answer

We often get calls from homeowners across New Jersey who are frustrated with uneven floors or cracked slabs. One case that stands out came from a family in Bridgewater, NJ. They had a basement floor with a noticeable dip running through the middle. After doing some online research, they thought self-leveling concrete (SLC) was the answer. They even considered pouring it themselves after watching a few videos.

Fortunately, they reached out to us first. During our inspection, we discovered the issue wasn’t simply surface-level unevenness. The slab was actually sinking due to poorly compacted soil underneath. If they had gone ahead with SLC, it might have looked smooth for a few months, but the floor would have continued sinking. In fact, the added weight of the self-leveling mix could have made the problem worse.

Instead of wasting time and money on the wrong solution, we recommended mudjacking to raise and stabilize the slab. Within a day, their basement floor was level again, and the family could use the space safely without worrying about cracks or trip hazards returning.

This example highlights why it’s important to evaluate why your floor is uneven before choosing a fix. Self-leveling concrete is great when the slab itself is stable and only needs smoothing, but when the issue is soil settlement or voids, another method is needed. That’s where our expertise at The Concrete Chiropractor® makes the difference — we help you avoid costly mistakes and choose the repair that truly lasts.

Ready to Fix Your Uneven Floors? Let’s Talk.

At The Concrete Chiropractor®, we believe every repair should be done right the first time. Self-leveling concrete can be a smart option for surface smoothing, but it’s not always the answer for deeper problems like sinking slabs. That’s why we don’t just sell you on a service— we take the time to inspect your property, explain what’s really happening beneath your concrete, and recommend the solution that lasts.

If you’re in New Jersey and dealing with uneven concrete floors, sunken slabs, or cracked walkways, give us a call. We’ll help you decide if self-leveling concrete is the right approach or if another method will save you money and headaches in the long run.

- Local expertise with over 20 years of experience

- Honest assessments, not sales pitches

- Proven results across homes and businesses in NJ

If you are looking to do a search for concrete leveling contractors near me and live in the Central, Northern, or Southern New Jersey areas, or the Philadelphia, Bucks County, Lehigh County, or Northampton counties of Pennsylvania, don’t let uneven concrete cause more damage or safety risks. Contact The Concrete Chiropractor® today for a free evaluation and find out the best way to restore your concrete.

Your home deserves a solid foundation — and we’re here to make sure it gets one. Call us now or fill out our contact form to schedule your inspection.

Frequently Asked Questions About Self-Leveling Concrete

Can I apply self-leveling concrete myself, or should I hire a professional?

Technically, yes, you can buy bags of self-leveling concrete at most hardware stores and try it yourself. However, many homeowners underestimate how quickly the material sets. You have a very short window — sometimes only 15 to 20 minutes — to mix, pour, and spread it correctly. If you don’t prep the surface right or mix the ratio properly, the material can fail, leading to cracks, uneven coverage, or wasted money. Hiring a professional ensures proper bonding, leveling, and long-term performance.

How thick can self-leveling concrete be poured?

Most products are designed to be poured between 1/8 inch and 1 inch thick in a single application. Some specialty mixes allow thicker pours, but those require careful planning. If your floor has deep dips or large voids, SLC may not be the best solution. In cases where more than an inch or two is needed, slab raising or replacement may be more effective.

Will self-leveling concrete fix a sinking or cracked slab?

No, and this is where homeowners often get misled. SLC is designed to smooth out surface imperfections — not to lift or structurally repair a slab that’s sinking due to soil problems. If your concrete is uneven because the ground underneath has shifted, SLC will only mask the problem temporarily. Over time, the slab may continue to settle, and the self-leveling layer will crack along with it.

How long before I can use the floor after applying SLC?

In most cases, light foot traffic is safe within 4 to 6 hours. For heavier use or installing flooring materials, 24 hours is recommended. However, drying times depend on the thickness of the pour and humidity levels. Always check the manufacturer’s guidelines.

Is self-leveling concrete permanent?

When applied in the right situation, it can last for years. But permanence depends on the condition of the existing concrete and the stability of the soil below. That’s why we always inspect before recommending SLC. Sometimes, replacement or mudjacking is the smarter investment.

- How We Raised a Sunken Concrete Walkway in Sewell, NJ - November 20, 2025

- Carbon Fiber Foundation Repair: All You Need to Know - November 20, 2025

- 5 Common Causes of Concrete Porch Collapse (and How to Prevent It) - November 20, 2025