IN THIS ARTICLE

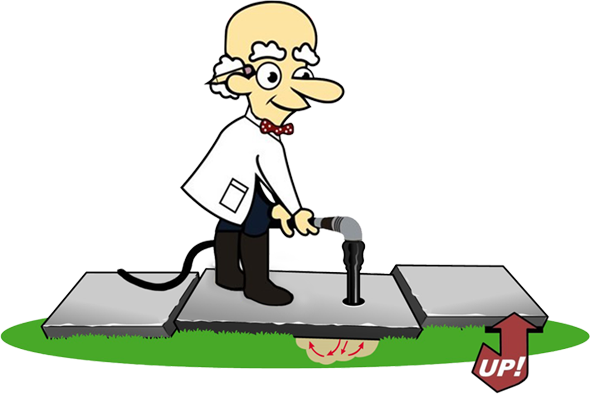

Concrete raising and lifting is best performed with a high strength, time proven material. This video documents the strength of our material through ” concrete compressive strength ” testing. Through proper quality control, we achieve five to ten times the strength of current polyleveling foam on the market, providing a superior strength of 561 to 1088 psi, versus an average of only 100 psi. poly foam. We have based our decision to not offer poly isocyanate foam on the following factors:

- Our product does not have the environmental and recycling concerns of a petroleum based, “polyurethane” or plastic foam material. Concrete that is recycled, crushed, and reused as a base for compaction, has no provisions to include poly foam contaminants. These poly foam products must be recycled separately at a much higher cost. Separation of a poly product when stuck to concrete is another concern, complicating the disposal process and increasing costs.

- As we move toward an environmentally friendly approach, we notice the banning of plastic bags, straws, and other poly-based products that are not biodegradable, having a negative long term environmental impact. Concrete and cement products have been used for thousands of years without the above concerns, all while providing long term durability.

- We realize that poly foam manufacturers see a great financial benefit in providing a costly product. Supply control can lead to high profit margins through each installation contractor. However, based on over four decades of construction knowledge, and over two decades as concrete raising specialists, we chose to focus on facts and offer our customers the best product based on those facts.We have chosen to avoid the long-term exposure and negative health effects associated with poly products on our employees. Osha and CDC recommendations while working with poly isocyanate foam requires cumbersome personal protective equipment due to safety concerns that range from toxicity and inhalation issues to flammability and skin absorption. Portland cement based products do require protective equipment, but to a much lesser degree.

- Poly foam is marketed under the concept that is does not contribute to settlement due to it being lightweight. By combining factors regarding the cause of concrete settlement, and taking them into consideration, we consider this poly foam “marketing strategy” to be grossly misrepresenting for the following reasons and can be easily disproven by the following:

- Weight is not the major contributing factor in soil settlement. The number one cause of concrete settlement is poor soil compaction. Based on volume and depth, such as next to a home foundation wall, this settlement can take place for well over a decade. Any product or repair method such as poly foam, portland cement mudjacking, or even replacement, is only as stable as the base it rests on. If soil settlement continues, concrete failure will continue to occur. Our experience has shown this to be a proven fact! Backfilled soils closest to foundation walls, trenches, or embankments, settle without concrete or weight placed on the surface. If you place poly foam itself ontop of a loose soil surface, it is guaranteed to settle along with the soil. The average two story home weighing approximately 240,000 to 350,000 pounds, rests on footings that are placed on ” undisturbed soils” that are not subject to movement. The cause of failure is the home’s surrounding “disturbed soils”.

- We have heard claims that poly foam expands, compressing loose soils. Poly foam, along with cement grout raises concrete by volume and expansion. These products do not magically find their way several feet below a concrete surface to a depth where soil settlement begins. We feel this is another gross misrepresentation or ” marketing strategy”.

- Poly foam will not wash away. Neither will a cement grout with a portland cement binder, that is 5 times or more the strength of poly foam. We all know plastics do not wash away or break down. Is this an asset? There has been a reduction in the use of plastics due to landfill and environmental concerns. Base soils that poly foam, cement grout, or concrete itself rest on, must have water issues corrected for a long-term result. In addition to soil erosion, water is a contributing factor related to concrete frost damage and deterioration.

- 5/8″ poly foam drill holes versus 1″ grout holes. If you place a dime on top of a quarter, this will demonstrate the difference in size. What it will not demonstrate is what the holes will look like when your technician has completed the patching. We have seen poly holes become nearly 3″ in size!

- Poly foam has been known to stick to and destroy concrete surfaces, home siding, and more and is does not wash off. Causing permanent damage. Concrete Chiropractor promises to provide quality materials, service, and experience to our customers!

- Mudjacking Cost: 5 Factors That Affect It - April 10, 2024

- What is The Average Cost of Concrete Leveling in Belle Mead, NJ? - April 4, 2024

- Unveiling the Top Pool Deck Resurfacing Options: Choosing the Best for You - March 26, 2024